Q8 Formula Truck 7000 15W40, our new top tier heavy duty diesel engine oil, is designed to protect engines against bore polishing. You may well ask how engine oil can possibly do this. To answer this question one needs to understand what bore polishing is and how it is brought about.

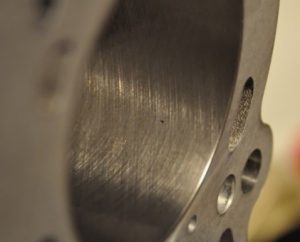

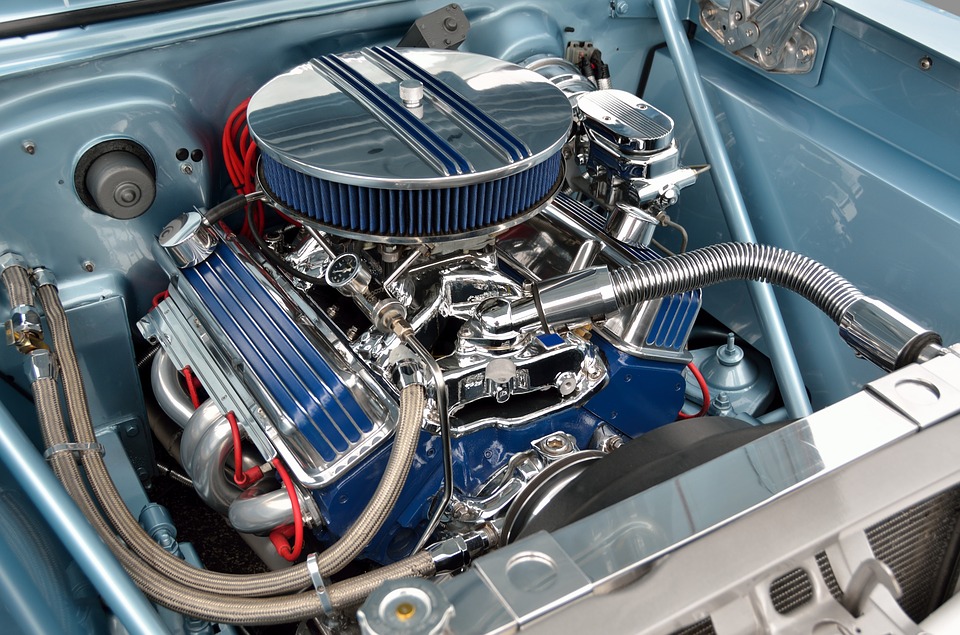

When modern engines are manufactured, the cylinder bores are honed (machined) to produce a “crosshatch” appearance with fine grooves from both directions at about 22 degrees from the horizontal (Photo 1). The crosshatch pattern is required to retain oil to ensure proper lubrication and to form a seal between the piston rings and cylinder bores. Bore polishing is characterized by a clearly defined area of bright mirror-like finish on the cylinder bore where the crosshatch pattern is worn away (Photo 2).

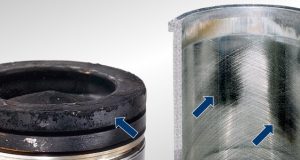

Bore polishing is brought about by a build-up of carbon deposits in the piston top ring land area, i.e. the part of the piston above the top ring (Photo 3). Poor combustion of diesel fuel leads to these hard carbon deposits, which are highly abrasive and scrape away the honing grooves on the cylinder bores. Bore polishing leads to increased oil consumption (blue exhaust smoke) and loss of combustion pressure. This is because the oil film trapped in the honing grooves that maintains the piston ring seal and combustion pressure, is no longer there. Unburned fuel and combustion gases then leak past the piston rings and contaminate the lubricating oil.

Bore polishing is brought about by a build-up of carbon deposits in the piston top ring land area, i.e. the part of the piston above the top ring (Photo 3). Poor combustion of diesel fuel leads to these hard carbon deposits, which are highly abrasive and scrape away the honing grooves on the cylinder bores. Bore polishing leads to increased oil consumption (blue exhaust smoke) and loss of combustion pressure. This is because the oil film trapped in the honing grooves that maintains the piston ring seal and combustion pressure, is no longer there. Unburned fuel and combustion gases then leak past the piston rings and contaminate the lubricating oil.

The problem is aggravated by the formation of acids in the engine oil resulting from the reaction of these combustion by-products and condensed water. The acidic build-up in the oil causes corrosive wear of engine components. This cycle of degradation results in the engine becoming irreversibly damaged. The advanced detergent additive system in Q8 Formula Truck 15W-40 protects diesel engines against bore polishing by effectively removing carbon deposits from piston top ring land areas.

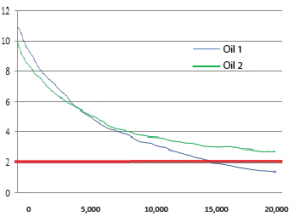

A number of engine tests have been developed to evaluate the bore polishing tendency of diesel engine oils. One such test is the CEC L-101-08 procedure using a Mercedes Benz OM501LA engine. In addition to bore polishing, the test also evaluates piston cleanliness, oil consumption, and engine sludge. Q8 Formula Truck 7000 15W-40 exceeds the requirement of the CEC L-101-08 test protocol by far.

To find out more about what Q8 Formula Truck 7000 15W-40 can do for your engines, please visit https://www.facebook.com/BlueChipLubricants/

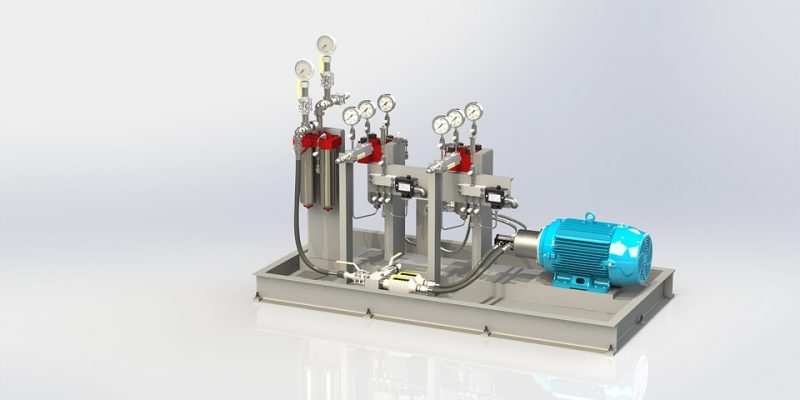

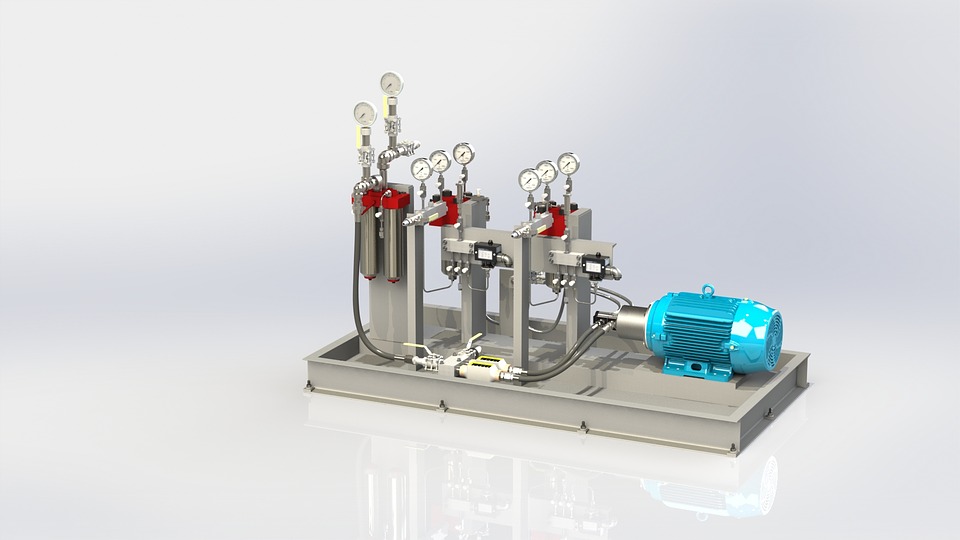

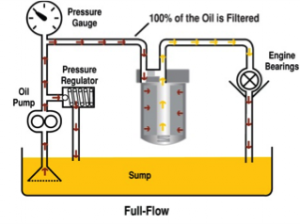

In a system where the pump is positioned higher than the oil sump, such as an automotive engine, this will present a serious problem. We will endeavour to explain this using honey as an example. At normal room temperature honey will be above its Pour Point. When you open a jar of honey and turn it upside down, the honey will flow out under the force of gravity. Yet at the same temperature, it will be impossible to suck the honey out of the jar with a straw although the honey is still above its Pour Point. Now compare this with the engine oil circulating system on the right.

In a system where the pump is positioned higher than the oil sump, such as an automotive engine, this will present a serious problem. We will endeavour to explain this using honey as an example. At normal room temperature honey will be above its Pour Point. When you open a jar of honey and turn it upside down, the honey will flow out under the force of gravity. Yet at the same temperature, it will be impossible to suck the honey out of the jar with a straw although the honey is still above its Pour Point. Now compare this with the engine oil circulating system on the right.

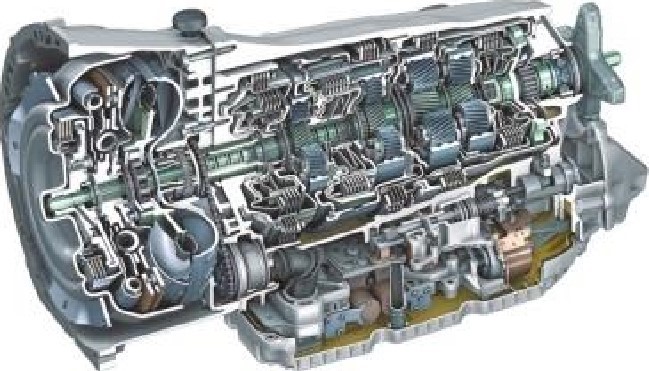

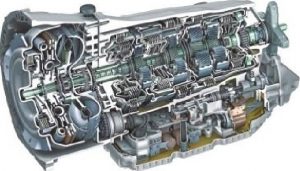

and drivability. Various top of the range luxury cars are now available with eight-, nine- and even ten-speed auto boxes. These transmissions are incredibly sophisticated with many of them requiring their own specific fluid formulations, such as the Mercedes-Benz 9G-Tronic transmission on the right.

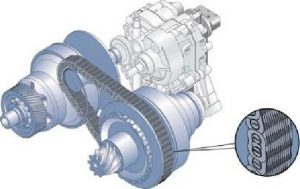

and drivability. Various top of the range luxury cars are now available with eight-, nine- and even ten-speed auto boxes. These transmissions are incredibly sophisticated with many of them requiring their own specific fluid formulations, such as the Mercedes-Benz 9G-Tronic transmission on the right. In CVT’s fitted to cars the rubber belt is replaced with a metal belt or chain running between the variable-diameter pulleys. This poses a unique set of different challenges as opposed to traditional ATF’s such as requiring higher shear stability and maintaining the appropriate amount of metal-to-metal friction while having enhanced anti-shudder performance. As in the case of ATF’s, there is not one universal CVT fluid that is suitable for all Continuously Variable Transmissions.

In CVT’s fitted to cars the rubber belt is replaced with a metal belt or chain running between the variable-diameter pulleys. This poses a unique set of different challenges as opposed to traditional ATF’s such as requiring higher shear stability and maintaining the appropriate amount of metal-to-metal friction while having enhanced anti-shudder performance. As in the case of ATF’s, there is not one universal CVT fluid that is suitable for all Continuously Variable Transmissions.