In response to OilChat #69 (Overfilling Engine Oil) the question was asked if it is possible for the oil level to rise on the dipstick between services even if no oil was added to the engine. The answer is YES and the reason is that the oil may get contaminated with water, fuel or engine coolant.

Water: As engines heat up and cool down condensation is formed. Some of the condensed water ends up in the engine oil, but normally condensation is not too much of an issue. Of more concern is the water formed during the combustion process in petrol and diesel engines.

For every litre of fuel burned in an engine, approximately one litre of water is formed in the combustion chamber. At operating temperature this is not a problem since the water goes out through the exhaust in vapour form (steam). When the engine is cold, however, some of the water gets past the piston rings into the oil sump. Water is one of the most destructive contaminants in lubricants. It attacks oil additives, causes rust and corrosion, induces base oil oxidation and reduces oil film strength.

Fuel: Fuel dilution of the engine oil can occur due to several reasons, including internal leakage of the fuel injection system, dirty or faulty fuel injectors, extended periods of idling and frequent cold starts.

Internal leakage can be related to injector sealing ring failure and loose components. A dirty or faulty fuel injector will cause ‘dribbling’ of liquid fuel into the combustion chamber and it may end up in the crankcase where it dilutes the oil. An idling engine is not operating at optimum performance and leads to incomplete fuel combustion. Extended periods of idling result in unburned fuel getting past the rings and running down into the crankcase oil. Furthermore, during cold starts some of the atomised fuel comes into contact with the cold cylinder walls, condenses and ends up in the crankcase where it dilutes the oil. On the way down the fuel also washes the oil on the cylinder walls away, resulting in accelerated ring, piston and cylinder wear.

In addition fuel dilution of the oil in the crankcase results in premature depletion of the alkalinity of the oil (base number or TBN) that leads to loss of corrosion protection, deposit formation and degradation of the oil.

Engine Coolant: Glycol and water in the engine cooling system may enter an engine as a result of defective seals, blown head gaskets, cracked cylinder heads and corrosion damage. Glycol reacts with oil additives and reduces the ability of the oil to protect engine components. Furthermore, less than 1% glycol contamination is enough to drop out soot dispersed in the oil, leading to sludge formation, restricted oil flow and blocked filters.

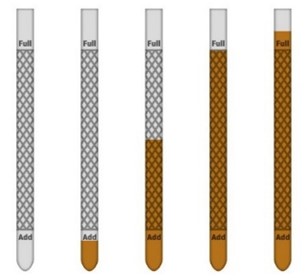

In OilChat 69 we discussed the dangers of too much oil in the crankcase and how it can ruin an engine. Not only will these contaminants raise the level of the oil in the crankcase, it may also damage the engine as discussed above. It is therefore in your own interest to check your engine oil level regularly and to ensure that it stays between the upper and lower limits on the dipstick.

If the oil level changes drastically in a relative short period of time you may have a serious problem. Do not start the engine and investigate as soon as possible. If you are not confident doing this yourself, you will need to get your vehicle towed to a mechanic or service centre – driving it could damage the engine, requiring expensive repairs. Whatever the cause of the high oil level, the condition needs to be corrected without delay.

Raison d’etre for API GL-6 surfaced in the mid 1960’s when Ford needed better protection in their pickup trucks and GM developed the revolutionary front wheel drive Oldsmobile Toronado.

Raison d’etre for API GL-6 surfaced in the mid 1960’s when Ford needed better protection in their pickup trucks and GM developed the revolutionary front wheel drive Oldsmobile Toronado.

lly designed for use in hydraulic brake systems fitted to modern mountain bikes. Due to its special formulation, Blue Chip Brakz is suitable for all cycle brake systems that require mineral or synthetic based brake fluid. Brakz is dyed green for easy identification and is available in handy resealable 125 ml plastic sachets.

lly designed for use in hydraulic brake systems fitted to modern mountain bikes. Due to its special formulation, Blue Chip Brakz is suitable for all cycle brake systems that require mineral or synthetic based brake fluid. Brakz is dyed green for easy identification and is available in handy resealable 125 ml plastic sachets.