The brake system is possibly the most neglected component of motorcars. Most drivers check tyre pressures and change engine oil at frequent intervals, but very few motorists replace the brake fluid in their car regularly. If you don’t change your engine oil the worst that can happen, is the engine may seize and your car will come to a standstill. On the contrary, if something goes wrong with the brake system, the car will not stop – with possible catastrophic consequences!

The prime function of brake fluid is to provide a hydraulic medium with a low level of compressibility, to transmit the driver’s foot pressure on the brake pedal to the brakes. Many automotive hydraulic brake systems in use today utilize front disk brakes and drums at the rear, but four wheel disk systems are also fairly common. When braking, the kinetic energy (energy of motion) of the vehicle is converted into heat in the brakes as the vehicle slows down. A tremendous amount of heat is generated to stop a vehicle from even a modest speed, particularly in disc brakes. The brake fluid is in close contact with the brakes and this can lead to overheated brake fluid.

Overheated brake fluid can boil in the brake lines. Boiling produces vapour (gas bubbles) within the brake fluid. Vapour is compressible and boiling brake fluid leads to a “spongy” brake pedal with long travel. In extreme cases overheated brake fluid requires that the brake pedal be “pumped’ (if you are fortunate enough to have time to do so) in order to get the brakes to respond. This necessitates a closer look at the boiling point of brake fluid.

Most brake fluids used today are glycol-ether based, but silicone type fluids are also available. Brake fluids must meet certain requirements as defined by various institutions. These include the Society of Automotive Engineers (SAE) J1704 standard and the US Department of Transport (DOT) FMVSS 116 specifications DOT 3, DOT 4 and DOT 5.1 (glycol-ether based) and DOT 5 (silicon based). All specifications include minimum boiling points for brake fluid.

Using glycol-ether fluids is the most economical way to meet brake fluid requirements and they are almost incompressible. Glycol-ether, however, is hygroscopic which means it absorbs moisture from the atmosphere. These brake fluids start to absorb moisture from the moment they are put into the hydraulic brake system or exposed to the atmosphere. The fluid attracts moisture through microscopic pores in rubber hoses, past leaking seals and exposure to air in the brake fluid reservoir. The problem is obviously worse in wet climates where humidity is high. Moisture reduces the boiling point of the fluid significantly. Minimum boiling point limits are therefore specified for new (dry) brake fluid, as well as fluid contaminated with moisture (wet brake fluid). Wet Boiling Point is defined as the temperature brake fluid will begin to boil after it has absorbed 3.7% water by volume. Silicone fluids are non-hygroscopic which means they can maintain a higher boiling point over the service life of the fluid. A disadvantage of silicone is that it is more compressible than glycol based fluids, resulting in a “soft” brake pedal with longer travel. The differences in the boiling points of the various brake fluid specifications are listed in the table below:

| FMVSS 116 | Dry Boiling Point | Wet Boiling Point |

| Specification | (minimum) | (minimum) |

| DOT 3 | 205 °C | 140 °C |

| DOT 4 | 230 °C | 155 °C |

| DOT 5 | 260 °C | 180 °C |

| DOT 5.1 | 260 °C | 180 °C |

DOT 5.1 glycol-ether based brake fluid has been developed to be identical to DOT 5 silicone based fluid in boiling points but without the ‘compressibility’ of silicon fluids. Brake fluids with different DOT ratings cannot always be mixed. It must be of the same type, and at least the same or higher rating. DOT 5.1 can, therefore, replace DOT 4

and DOT 3. Likewise, DOT 4 can replace DOT 3 but not vice versa. Never mix DOT 5 silicon based brake fluid with regular glycol based fluids. None of these should be mixed with DOT 5 as the mixing of glycol and silicone fluids may lead to brake failure.

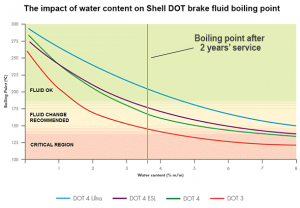

The boiling points in the table above are minimum specifications and therefore you may well find DOT 4 brake fluids with boiling points above that of DOT 5 and DOT 5.1 specifications. Today DOT 4 is the most commonly used brake fluid and the dry boiling point of most of these fluids exceeds 260°C. The effect of water content on boiling point over time is illustrated by the graph below. The graph (by courtesy of Shell) demonstrates the declining effect water content has on the boiling point of a typical DOT 3 (red curve) and three DOT 4 brake fluids:

The Impact of Water Content on the Boiling Point of Brake Fluid

We mentioned earlier that DOT specifies the minimum wet boiling point of brake fluid after absorbing 3.7% water. On average this occurs after two years in service. The graph illustrates that in most instances warning limits are reached within this period. It is therefore little wonder that most vehicle manufacturers recommend that brake fluid should be changed every eighteen to twenty-four months. The graph also shows that the boiling points of the various brake fluids decline even further over extended periods of time. When the DOT 3 brake fluid reaches 8% water content the boiling point is reduced almost to that of water!

Brake fluid is crucial to the safe operation of your vehicle. Check your owner’s manual for the recommended brake fluid replacement schedule and brake fluid type. Remember, brake fluid is what is between your brake pedal and the brakes at the wheels. Make brake fluid part of your regular maintenance routine, and replace the brake fluid when necessary to keep you and your passengers safe.

It is also important to remember that brake fluid is toxic and combustible and can damage the paintwork of your vehicle.