Welcome to the eightieth edition of our newsletter. OilChat was introduced way back in October 2015 in response to requests and suggestions from our customers, distributors and our own sales team. The objective was a regular publication to share topical information about the oil industry, and lubrication in particular.

The topic of the inaugural issue of OilChat was Lubricating Base Oil since it is the foundation of most lubricants. The following editions of the newsletter focused on various basic subjects, such as viscosity, lubricant additives, oil formulations and lubricant specifications, to furnish our OilChat readers with a sound knowledge of the basics of lubrication. Thereafter lubricant applications were the key discussion subjects, with The Journey of Oil in the Engine one of the most popular topics.

More recently we have been writing about a broad range of lubrication related issues based on what is happening in the oil industry, new developments and topics of importance to everyone with interest in lubrication. Last, but certainly not least, some of the articles were based on questions and suggestions from you, our readers.

All previous editions of OilChat are still available on our website and are a useful encyclopedia of information on many aspects of lubrication and the oil industry. In fact, if you are au fait with the contents of all the newsletters you will be very much on par with delegates that have attended one of our Basic Lubrication Courses. To access our newsletters simply go to www.q8oils.co.za and click on the tab OilChats at the top of the homepage.

The newsletters are listed in numerical order but considering the number of OilChats that were issued since October 2015, it may be quite time consuming to find a bulletin dealing with a specific topic. To simplify your search we attach an index of all the OilChat topics we have published to date. In conclusion we wish to thank all OilChat followers for the loyal support of our forum. We want this newsletter to be of continued interest and value to you, so please share your feedback and suggestions with us to help us to improve your OilChat experience. Please mail any recommendations or questions that you may have to info@bcl.co.za or phone us at 011 462 1829.

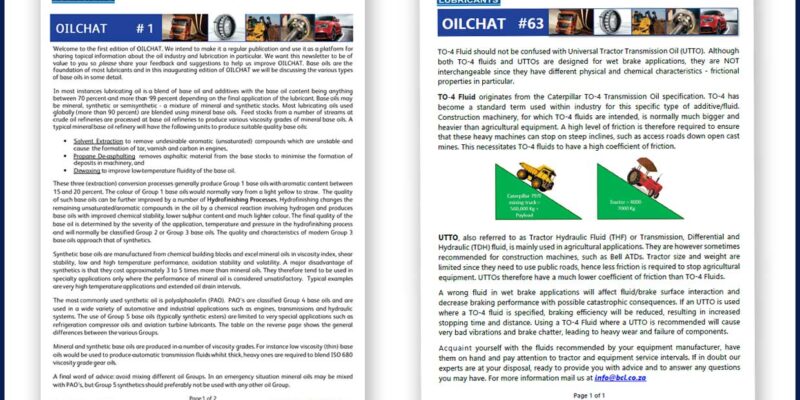

INDEX OF OILCHAT TOPICS

| No | TOPIC | No | TOPIC | No | TOPIC |

| 1 | Lubricant Base Oil | 28 | Automatic Transmission Fluid | 55 | Covid-19 and the Oil Industry |

| 2 | Viscosity and Viscosity Index | 29 | Borderline Pumping Temperature | 56 | AW vs EP additives Pt 1 |

| 3 | SAE Engine Oil Viscosity Grades | 30 | Hydraulic Oil Selection | 57 | AW vs EP additives Pt 2 |

| 4 | SAE Gear Oil Viscosity Grades | 31 | New Q8 Diesel Engine Oil | 58 | Chainsaw Lubrication |

| 5 | Industrial Oil Viscosity Grades | 32 | Total Base Number | 59 | Heat Transfer Oil |

| 6 | Industrial Gear Oil Classification | 33 | Cylinder Bore Polishing | 60 | Multigrade vs Monograde Oil |

| 7 | Engine Oil Composition | 34 | Cylinder Bore Glazing | 61 | Bicycle Service Products |

| 8 | API Petrol Engine Oils | 35 | Viscosity Index Improvers | 62 | API GL-6 Gear Oil |

| 9 | API Diesel Engine Oils | 36 | Detergent Dispersant Additives | 63 | UTTO vs TO-4 Fluid |

| 10 | Q8Oils Antwerp Blending Plant | 37 | Metal Working Fluid | 64 | All About AdBlue |

| 11 | ACEA Engine Oil Sequences Pt 1 | 38 | Metal Working Fluid Management | 65 | Rock Drill Lubricants |

| 12 | ACEA Engine Oil Sequences Pt 2 | 39 | Slideway Lubricants | 66 | To Flush or Not to Flush |

| 13 | API Gear Oil Classifications | 40 | Limited Slip Diff Lubrication | 67 | Contamination Destroys Hydraulics |

| 14 | Automotive Gear Oil Applications | 41 | Fuel Economy vs Engine Wear | 68 | Grease Intervals and Amounts |

| 15 | Lubricating Grease Pt 1 | 42 | HTHS Viscosity | 69 | Overfilling Engine Oil |

| 16 | Lubricating Grease Pt 2 | 43 | Lubricant Storage Life | 70 | Engine Oil Level Rising |

| 17 | Universal Tractor Lubricants | 44 | Two-Stroke Engine Lubrication Pt 1 | 71 | Diptstick Oil Analysis |

| 18 | Flash Point | 45 | Two-Stroke Engine Lubrication Pt 2 | 72 | Blotter Spot Engine Oil Test |

| 19 | ACEA Oil Sequences 2016 | 46 | Two-Stroke Engine Lubrication Pt 3 | 73 | Crackle Test for Water in Oil |

| 20 | Compressor Lubrication Pt 1 | 47 | Soot in Engie Oil | 74 | Cavitation |

| 21 | Compressor Lubrication Pt 2 | 48 | Engine Oil Deterioration | 75 | Gear Wear Pattern Analysis |

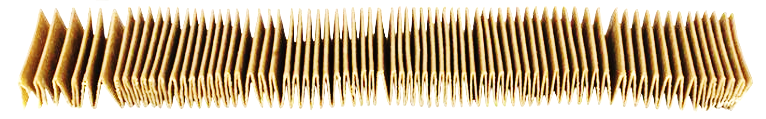

| 22 | Lubrication Regimes | 49 | Lubricant Aeration and Foaming | 76 | Oil Filter Analysis |

| 23 | Pour Point of Lubricating Oil | 50 | Base Oil Classification | 77 | Machine Health Checks |

| 24 | Grease Oil Separation | 51 | Chain Lubrication | 78 | The Danger of Water in Oil |

| 25 | Antifreeze Engine Coolant | 52 | Air Tool Lubrication | 79 | Extended Engine Oil Drain Intervals |

| 26 | The Journey of Oil in the Engine | 53 | History of Lubrication Pt 1 | 80 | Index of Topics |

| 27 | Brake Fluid | 54 | History of Lubrication Pt 2 |

Many modern engines use lightweight aluminium components and pinpointing the origin of shiny aluminium particles in the oil filter can be difficult. One area that experiences regular wear is the piston skirt. Abnormal wear of the piston skirts is often due to contamination that has entered the combustion chamber or the use of the wrong engine oil. Checking the air intake and filter system is a good idea if you believe contamination has entered the engine.

Many modern engines use lightweight aluminium components and pinpointing the origin of shiny aluminium particles in the oil filter can be difficult. One area that experiences regular wear is the piston skirt. Abnormal wear of the piston skirts is often due to contamination that has entered the combustion chamber or the use of the wrong engine oil. Checking the air intake and filter system is a good idea if you believe contamination has entered the engine. Other small, shiny particles that can be confused with aluminium are tin, lead and copper. These materials are often used in the Babbitt alloy layer of the main and piston rod small end bearings. Insufficient lubrication of these bearings can lead to premature wear of the Babbitt layer and eventually to the failure of the bearing. If remnants of tin, lead or copper are found, it would be wise to ensure that the engine is being properly lubricated with the correct oil.

Other small, shiny particles that can be confused with aluminium are tin, lead and copper. These materials are often used in the Babbitt alloy layer of the main and piston rod small end bearings. Insufficient lubrication of these bearings can lead to premature wear of the Babbitt layer and eventually to the failure of the bearing. If remnants of tin, lead or copper are found, it would be wise to ensure that the engine is being properly lubricated with the correct oil. In many cases, you will find some amount of carbon, which is difficult to identify, but the use of a magnifying glass can help. When rubbing carbon between your fingertips it will feel slightly gritty but it will break apart easily. Carbon accumulation is typically a result of blow-by getting past the piston rings. If your engine suffers from excessive oil consumption and low cylinder compression readings, you most probably have worn or damaged piston rings.

In many cases, you will find some amount of carbon, which is difficult to identify, but the use of a magnifying glass can help. When rubbing carbon between your fingertips it will feel slightly gritty but it will break apart easily. Carbon accumulation is typically a result of blow-by getting past the piston rings. If your engine suffers from excessive oil consumption and low cylinder compression readings, you most probably have worn or damaged piston rings.

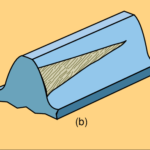

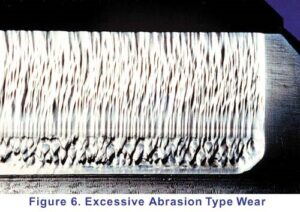

Abrasion can range from mild to severe. Very mild abrasion may cause polishing of gear teeth. Moderate abrasion consists of fine scratches with little removal of material from the contact surfaces. Severe abrasion manifests itself as deep grooves on gear teeth as shown on the right. Abrasive wear is brought about by particle contamination of the oil or rough gear surfaces as discussed below:

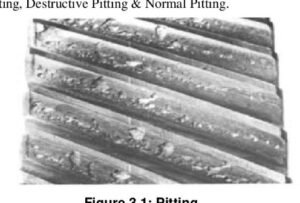

Abrasion can range from mild to severe. Very mild abrasion may cause polishing of gear teeth. Moderate abrasion consists of fine scratches with little removal of material from the contact surfaces. Severe abrasion manifests itself as deep grooves on gear teeth as shown on the right. Abrasive wear is brought about by particle contamination of the oil or rough gear surfaces as discussed below: The formation of pits or holes on gear teeth is called pitting and is caused by overload conditions on the gear tooth surface. Severe pitting is also referred to as spalling. A pit forms when small cracks (due to overloading) grow long enough to separate a piece of material at the surface. These irregularities cause additional friction and result in a lot of heat being generated, which in turn reduces the viscosity of the oil. A possible solution would be to use an EP oil with higher viscosity.

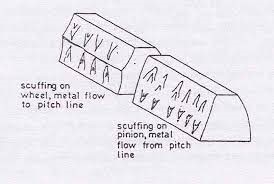

The formation of pits or holes on gear teeth is called pitting and is caused by overload conditions on the gear tooth surface. Severe pitting is also referred to as spalling. A pit forms when small cracks (due to overloading) grow long enough to separate a piece of material at the surface. These irregularities cause additional friction and result in a lot of heat being generated, which in turn reduces the viscosity of the oil. A possible solution would be to use an EP oil with higher viscosity. Scuffing or scoring can be described as grooves over a wide area of gear teeth. Scuffing leads to the much more serious wear mechanism referred to as galling as seen on the left. It occurs when a lack of lubrication causes metal-to-metal contact of gear teeth, resulting in elevated temperatures. This can result in localized welding in contact areas. Metal is then ripped from one surface and transferred to the other. This type of wear is also referred to as adhesive wear.

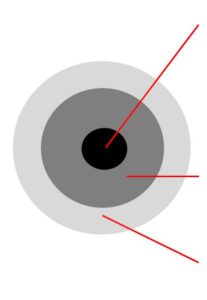

Scuffing or scoring can be described as grooves over a wide area of gear teeth. Scuffing leads to the much more serious wear mechanism referred to as galling as seen on the left. It occurs when a lack of lubrication causes metal-to-metal contact of gear teeth, resulting in elevated temperatures. This can result in localized welding in contact areas. Metal is then ripped from one surface and transferred to the other. This type of wear is also referred to as adhesive wear. On driven gears metal ‘flows’ towards the middle of the gear teeth, along the length of gear teeth, as shown above and on the left gear tooth in the adjacent diagram. On driving gears metal propagates away from the centre line of the gear as depicted on the far right. Possible solutions would be to use an EP oil with a higher viscosity and reducing the temperature of the oil.

On driven gears metal ‘flows’ towards the middle of the gear teeth, along the length of gear teeth, as shown above and on the left gear tooth in the adjacent diagram. On driving gears metal propagates away from the centre line of the gear as depicted on the far right. Possible solutions would be to use an EP oil with a higher viscosity and reducing the temperature of the oil.

y the contaminant band should spread with the oil to leave a fairly even discoloration. When the oil is badly contaminated, the contaminants clump together and do not migrate with the oil front. This indicates that the dispersancy additive of the oil is depleted.

y the contaminant band should spread with the oil to leave a fairly even discoloration. When the oil is badly contaminated, the contaminants clump together and do not migrate with the oil front. This indicates that the dispersancy additive of the oil is depleted.