0ver-greasing or under-greasing:

which is the bigger problem when it comes to bearing lubrication?

To answer this question, it is important to understand that over-greasing and under-greasing can refer to two different things. It may mean that the volume pumped into a bearing during a greasing service can be too much or too little. It can also mean that regreasing services are occurring too often or too seldom. It can be difficult to determine which is the bigger problem, but the following discussion should help you decide what might cause the most damage in your specific application

Over-greasing by applying too much grease to a bearing may result in seal failure. If there is no relief port on the bearing housing, the excess grease will blow past the seals and damage them. This can present several problems since the grease that remains in the housing can leak out. It also provides a path for external contaminants to enter the housing.

In addition, a bearing housing overfilled with grease can generate heat. A big difference between grease and oil is that grease cannot transfer heat away from the load zone. Too much grease in a bearing can create heat from fluid friction. Because the heat has nowhere to go, it can degrade the grease by causing too much churning. If there are proper purge points to relieve excess grease, the only problem with greasing too often is that you will be purging good grease out of the bearing.

Under-greasing or not putting enough grease into a bearing housing can be just as detrimental, but it has the opposite effect than over-greasing. By not providing enough lubrication for the bearing, heat can be generated by the friction between the moving parts. Also, if there is a void inside the bearing housing, it can allow contamination to enter the load zones, resulting in damage to the moving elements.

Not greasing often enough would generally be considered a bigger problem. After an extended period of time, the grease may harden as a result of oxidation. This will cause excessive component wear due to lack of lubrication and the presence of possible contaminants. The best practice would be to avoid both these conditions.

It is therefore essential to acquaint yourself with the greasing procedures recommended by your equipment manufacturer. If such recommendations are not available, the following guidelines can be used to establish suitable greasing frequencies and amounts:

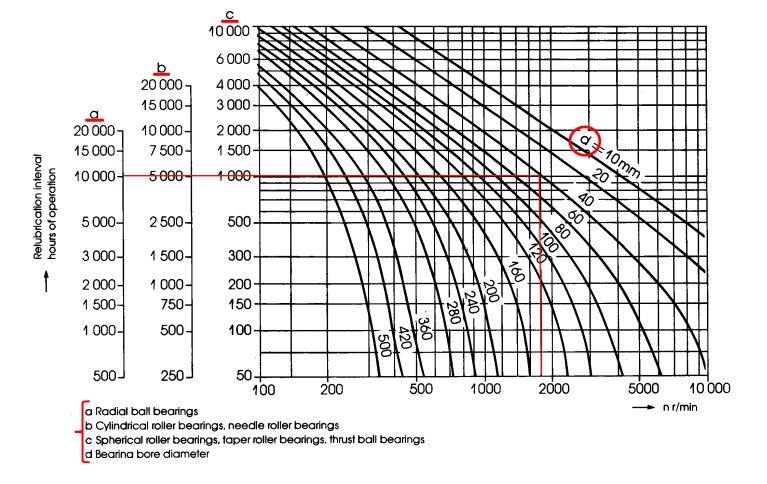

FREQUENCY: The chart below shows approximate relubrication intervals. Start at the bottom and select the bearing speed; go straight up until you meet the curve that matches your bearing I.D. (or d); then go straight left to see the relubrication interval (in hours) for your particular bearing type (a, b or c):

AMOUNT: To calculate the amount in grams, multiply OD in mm x Width in mm x 0.005

EXAMPLE: Let us say you have a 6209 ball bearing, running at 1,800 RPM, 24 hours a day, 7 days a week. A 6209 bearing has a shaft diameter (ID or d) of 45 mm, an OD of 85 mm, and a width of 19 mm. Using the chart and the formula, the bearing needs 8 grams of grease every 10,000 hours. If your grease gun delivers around 1.35 grams per stroke, the bearing needs 6 strokes every 13 months. You can also average it out to one stroke every 8 weeks.

To find out more about the complete Blue Chip grease portfolio phone 011 462 1829, email us at info@bcl.co.za or visit www.bcl.co.za