Motor oil has many functions to perform in the engine, but the primary one is to reduce friction between moving parts by separating the mating surfaces with a layer or film of oil. If the oil film is not sufficiently robust to separate the surfaces, they will come into contact with one another and cause wear and possibly irreparable damage. An important indication of the ability of an oil to separate moving surfaces is the viscosity of the oil.

In simple terms viscosity is the “thickness” of a liquid. For example, water will flow more readily than honey. That is because the viscosity of honey is high compared to that of water. We can therefore say that viscosity is an indication of the resistance to flow. In common engineering sense a liquid with a high viscosity will separate surfaces better than one with a lower viscosity. There is however a fine balance between the oil being thick or viscous enough to keep the moving surfaces apart and the oil being fluid enough to be pumped effectively in the engine.

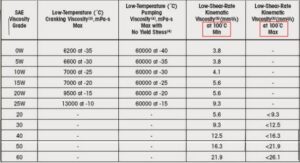

This is complicated by the fact that the viscosity of oil decreases with an increase in temperature and vice versa, therefore the temperature at which viscosity is measured must always be specified. The viscosity of lubricating oil is generally measured at 40⁰C and 100⁰C. The operating temperature of motor oil in modern engines is normally around 100⁰C and therefore the viscosity of engine oil is stipulated at this temperature as shown in the last two columns in the table below:

SAE J300 Engine Oil Viscosity Classification

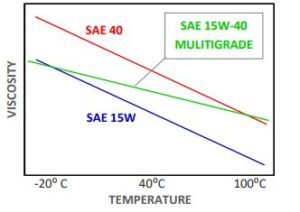

Oils defined by the SAE J300 classification system, cover a single requirement only and are known as monograde oils. The higher the SAE number the thicker the oil. The lower viscosity grades have a “W” (for winter) attached to the number. These oils must also conform to sub-zero viscosity requirements to make them suitable for low temperature applications. If we draw graphs of a typical SAE 15W and SAE 40 monograde oil with viscosity (plotted as a logarithmic function) on the vertical axis against temperature (as a linear function) on the horizontal axis, we come up with the blue and red lines in the diagram below:

The SAE 15W oil will flow sufficiently at low temperatures to protect engines during startup on cold mornings but will be too thin to provide adequate wear protection at operating temperatures. Contrarily the SAE 40 oil will perform satisfactorily when the engine is hot but will be too viscous to reach moving surfaces swiftly when cold. The solution? An oil that is ‘thin’ when cold but with a viscosity similar to a SAE 40 at operating temperature. To achieve this, we add a viscosity modifier (also known as a viscosity index improver) to the oil.

A viscosity modifier (VM) is an oil additive that is sensitive to temperature. When cold the VM contracts and does not impact the viscosity of the oil. At elevated temperatures it expands to increase the viscosity of the oil. If we start off with a thin oil (for argument’s sake the SAE 15W above) as base and add sufficient VM to meet SAE 40 viscosity limits at 100⁰C we have a SAE 15W-40 multigrade oil. Similarly there are SAE 5W-30, SAE 5W-40, SAE 10W-40, SAE 20W-50, etc. multigrade engine oils available in the market. In summary multigrade oils provide better engine protection at low and high temperatures than monogrades because they maintain optimum viscosity over the full engine operating temperature range.

If you have any questions regarding engine oil or any other lubricant related issues, simply mail us at info@bcl.co.za. Our experts are at your disposal and ready to provide you with advice and guidance.