Informally viscosity is known as the ‘thickness’ of a fluid. If you pour water into a container with a hole at the bottom, it drains in no time. However, if you fill the same container with honey, it drains much slower. Reason is that the viscosity of honey is high compared to that of water. You can therefore say the viscosity of a liquid is its resistance to flow.

Informally viscosity is known as the ‘thickness’ of a fluid. If you pour water into a container with a hole at the bottom, it drains in no time. However, if you fill the same container with honey, it drains much slower. Reason is that the viscosity of honey is high compared to that of water. You can therefore say the viscosity of a liquid is its resistance to flow.

More formally, viscosity is a measure of the internal friction of a fluid. Most liquids are cohesive. Cohesiveness is the intermolecular attraction by which the molecules of the fluid are held together and result in the internal friction of the fluid. This internal friction must be overcome by some force for the fluid to flow. A fluid with low viscosity flows easily because its chemical structure results in little friction when the molecules are in motion. There are various methods to measure the internal friction or resistance to flow, with the following two being the most frequently used for oil:

Kinematic Viscosity:

Kinematic Viscosity:

In kinematic viscometers the fluid flow is driven by gravity. This means the weight or density of the fluid helps it to flow. These viscometers measure the time that the fluid takes to flow through a capillary section in a viscometer tube. Each viscometer tube has a capillary constant. To obtain the kinematic viscosity, you multiply the measured flow time by the capillary constant. The unit for kinematic viscosity is centistoke (cSt). 1cSt equals 1 millimeter squared per second (mm2/s). The standard reference temperatures for kinematic viscosity measurements of lubricating oil are 40⁰C and 100⁰C

Dynamic Viscosity:

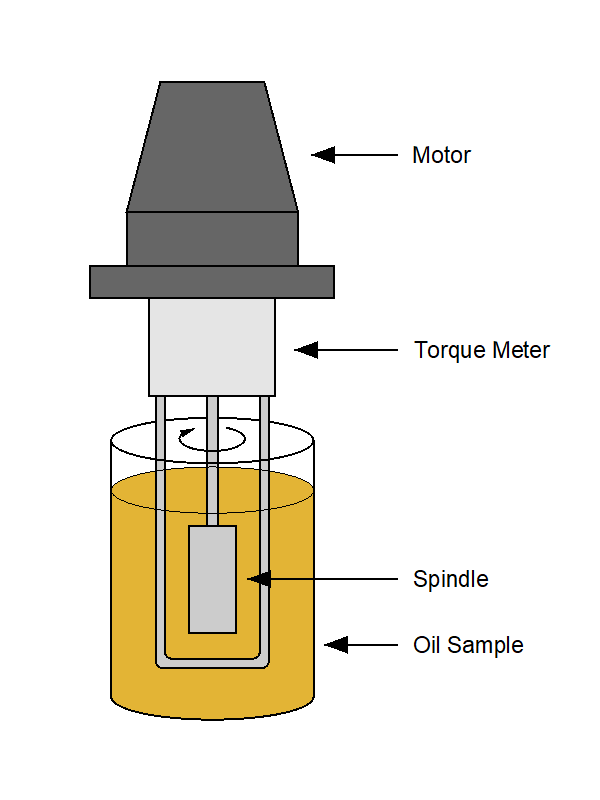

Fluid flow is induced by an external force in dynamic viscometers. Rotary viscometers are frequently used to measure the dynamic viscosity of oil. The test oil, kept at a stipulated temperature, is poured into the viscometer sample container and a spindle is inserted in the oil. The spindle is rotated at a specified RPM and the torque required to maintain the RPM is measured. The results are reported in centipoise (cP). 1cP is equal to 1 millipascal-second (mPa-s). Pascal is a unit of torque similar to kW and HP. Dynamic Viscosity is also known as Absolute Viscosity.

In summary of the above we can say that:

- Kinematic viscosity is the internal resistance of the oil to flow and shear under gravity.

- Dynamic viscosity refers to the resistance of the oil to flow when an external force is applied.

Simply put, kinematic viscosity indicates how fast the fluid flows under gravity, while dynamic viscosity denotes what force is required to make the fluid flow at a certain rate.

Kinematic viscosity incorporates fluid density as part of the measurement and therefore density provides a means to convert between kinematic and dynamic viscosity. The conversion formula is:

Kinematic Viscosity (cSt) x Density = Dynamic Viscosity (cP)

Kinematic or capillary viscometers are normally used to measure the viscosity of lubricating oils, typically at 40⁰C and 100⁰C. Rotational or absolute viscometers, however, are often employed for certain specific measurements. Multigrade motor oil is a typical example.

The viscosity grade of motor oil is specified by the Society of Automotive Engineers (SAE). Multigrade oils must conform to several viscosity requirements and their viscosity grade consists of two numbers, e.g. SAE 10W-40. The 10W represents the low temperature (Winter) specifications and the 40 specifies the high temperature requirements. The SAE Engine Oil Viscosity Standard J300 defines the limits for multigrade engine oils, using the following viscosity categories:

Kinematic Viscosity in cSt

- Low-Shear Viscosity at 100⁰C

Absolute Viscosity in cP

- Low-Temp Cranking Viscosity*

- Low-Temp Pumping Viscosity*

- High-Shear Viscosity at 150⁰C

*Temperature depending on viscosity grade.

In conclusion we emphasize that viscosity units of measure and viscometers are not restricted to what we have discussed above but we trust that this newsletter will clear some of the confusion around kinematic and dynamic viscosity.

If you have any questions about viscosity, you are welcome to email us at info@bcl.co.za