Heat Transfer Fluid or Thermal Fluid is a liquid that partakes in a heat exchange process. It moves heat (thermal energy) from one section of a system to another. Heat transfer fluids are used in countless applications and industrial processes which require heating or cooling – normally in a closed circuit and in continuous cycles. The cooling system of a vehicle is a typical example where the coolant removes heat from the engine and transfers it to the radiator to be cooled down.

Water is the most common heat transfer fluid owing to its low cost, high heat capacity and favorable heat carrying properties. The useful temperature range of water is, however, restricted by freezing at 0⁰C and boiling at elevated temperatures with the actual boiling point depending on the system pressure. For higher temperatures mineral oil is a popular alternative. Probably the most common example of an oil filled heat exchange system is the domestic oil heater.

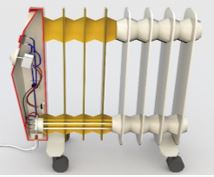

Oil heaters consist of metal columns with cavities that are filled with the heat transfer oil. A heating element at the base of the heater heats up the oil, which then flows through the cavities of the heater by convection (rising of the hot oil). The heat is transferred through the metal surfaces to the air on the outside. The surface area of the metal columns is large thus allowing lots of air to be in contact with the heater. This permits the heat to be transferred effectively, resulting in a surface temperature which is safe enough to touch.

In larger and industrial thermal fluid systems the oil is circulated with a pump (forced circulation) rather than by convection. Heat transfer systems may be open or enclosed, but almost all large industrial systems are of the closed loop design. This limits oxidation of the oil by preventing it to come into contact with oxygen in the atmosphere. A closed loop system with a single heat source (gas-fired, oil-fired, electric, biomass-fired, etc.) may be used to supply many different heating stations simultaneously and at different temperatures. The heat transfer oil capacity of such large and complex thermal fluid systems can be hundreds of liters and it is therefore essential that the oil should have a long service life. In addition, heat transfer oils must meet a number of other requirements depending on the specifics of the application. Some of the key criteria are:

Low viscosity enables adequate fluidity and promotes heat transmission.

Good heat stability controls oxidation and prevents sludge formation.

High boiling point prevents vaporization at elevated temperatures.

Large thermal capacity enables small volumes of oil to transfer large amounts of heat.

High flash point reduces the risk of fires, particularly in open systems.

Good solvency limits deposit formation and keeps heat exchange surfaces clean.

Low volatility prevents the buildup of pressure in the circulating system.

Noncorrosive formulation protects metal surfaces against rust and corrosion.

Good heat conductivity ensures effective heat transfer between oil and heat exchange surfaces.

To meet these requirements good quality mineral based heat transfer oils are formulated with highly refined base stocks and are compounded with functional additives to enhance the performance of the final product. As a rule of thumb adherence to the following temperature guidelines will ensure long service of mineral based heat transfer oils in thermal systems with forced circulation:

All it takes to keep your thermal system operating trouble-free are a few quick maintenance steps and the correct heat transfer oil. Making the right choice will enhance efficiency and increase the life of your heat transfer system. To help you make the best decision, simply mail us at info@bcl.co.za. Our experts are at your disposal and ready to provide you with advice and guidance.

We would also like to make use of this opportunity to wish all our readers, customers and followers a wonderful Festive Season and a prosperous New Year. We are certainly looking forward to chat to you again in 2022.