Cavitation is a phenomenon that occurs in various formats around us every day of our lives. In terms of fluid dynamics it can be described as the formation and collapse of cavities or bubbles in flowing liquids. Cavitation may well result in the pitting or erosion (wearing away) of solid surfaces, such as metal or concrete, that are in contact with the liquid.

Cavitation is often associated with components that rotate in a liquid, e.g. boat propellers, hydraulic oil pump elements and water pump impellers as shown on the right. Other common examples of cavitation are found in diesel engines with wet liners and where water is flowing over dam walls.

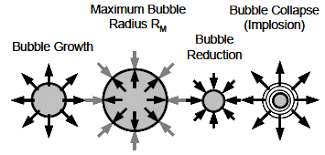

Surfaces in contact with a liquid undergo cavitation erosion or pitting due to pressure fluctuations in the surrounding liquid. In most instances the pressure fluctuations are generated by the movement of the surface itself. Following is a brief description of the cavitation process:

- Bubbles in the liquid grow when pressure decreases.

- Maximum bubble size at lowest pressure.

- Reduction in bubble size when pressure increases.

- Bubbles collapse (implode) when pressure is high enough.

The sudden volume contraction/collapse results in an energetic implosion accompanied by shock waves and high velocity microjets that impact and damage the solid surface.

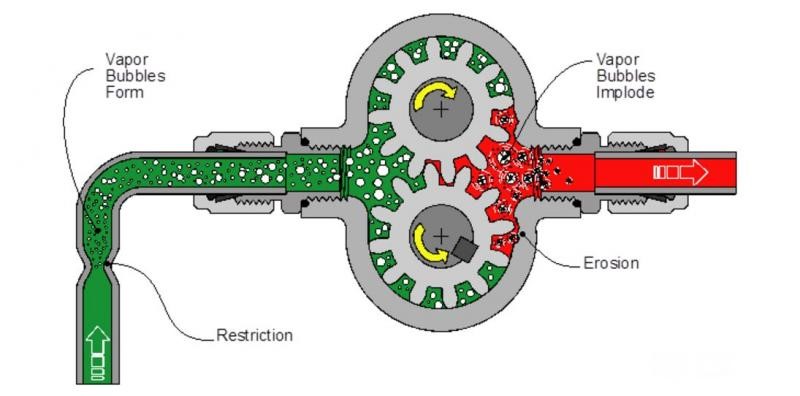

Vapour cavities or air bubbles may be present in a liquid due to various reasons. In the following diagram a restriction in the suction (low pressure) line of a hydraulic system results in the formation of vapour bubbles in the oil. As the oil passes from the suction side of the pump to the delivery (high pressure) side, the bubbles implode.

The imploding bubbles create the shockwaves that erode the internal pump components. The shockwaves also cause pump vibration and noise. A high speed hydraulic pump that sounds as if it is full of rocks or gravel is a sign of cavitation, which can lead to complete pump failure if you do not track down the cause.

By preventing cavitation, you will increase the efficiency and lifespan of your hydraulic pumps significantly. Keep an eye on internal parts for signs of pitting and corrosion and listen to the pump to ensure you do not hear what sounds like marbles banging around. If you have any questions about cavitation email us at info@bcl.co.za. Our lubricant experts will be happy to answer any questions you may have.