Tribology (from the Greek word ‘tribos’ meaning rubbing) can be described as the science of friction, wear and lubrication of interacting surfaces in relative motion to one another. Peter Jost, a British mechanical engineer, can be considered the founder of the discipline of tribology. In 1966 he published a report which highlighted the cost of friction, wear and corrosion to the British economy. It was in this report that the term tribology was originally used. The earliest systematic studies of tribology were, however, performed by Leonardo da Vinci, the first tribologist of the world, more than 500 years ago. He did not publish any of his findings but some of his notebook pages discovered more recently, contain amazing illustrations and observations related to friction.

FRICTION: Our ancestors first became familiar with friction in the Stone Age, when they discovered that they could create fire by rubbing pieces of wood against each other. We do not know for sure exactly when they mastered the art of making fire, but indications are that it was approximately 400,000 years ago. Leonardo da Vinci (1452 -1519) studied friction for more than 20 years of his life and understood very well that friction was a limiting factor in the design of his ‘revolutionary’ machines. He distinguished between various types of friction (the force that opposes the motion of a solid object over another) and noted that surface roughness has an impact on how easy it is to move different materials in contact with one another.

There are primarily four types of friction:

Static Friction is the frictional force between contacting surfaces when they are at rest with respect to each other. The magnitude of the static force is equal to and in the opposite direction of a force applied to move one surface. The maximum static friction is reached just before the surface starts to move.

Sliding Friction occurs when the surface of one object moves relative to the surface of another object. It is also called Kinetic Friction and it is the force required to keep a surface sliding over another surface.

Rolling Friction is defined as the force which resists the rolling motion of a round object (ball or wheel) over a surface. Rolling Friction is lower than Static and Sliding Friction.

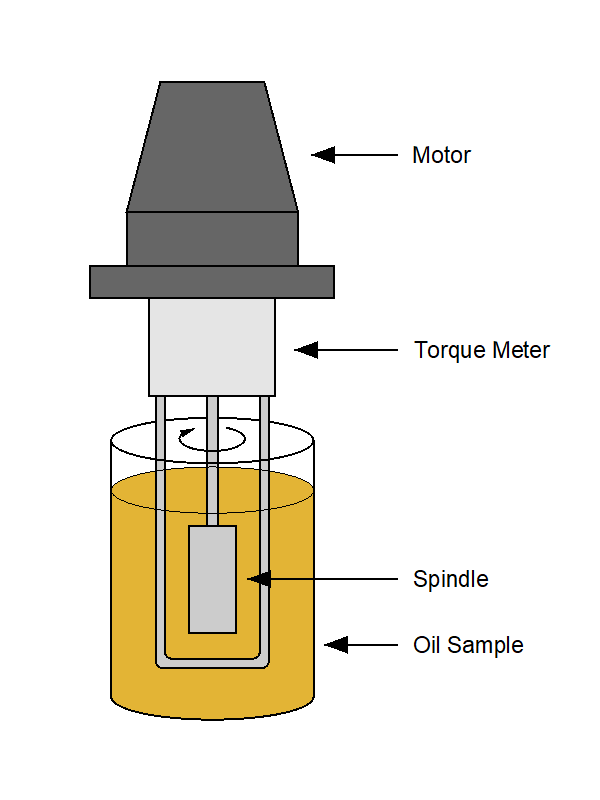

Fluid Friction occurs between the layers of a fluid that are moving relative to each other. This internal resistance to flow is termed viscosity.

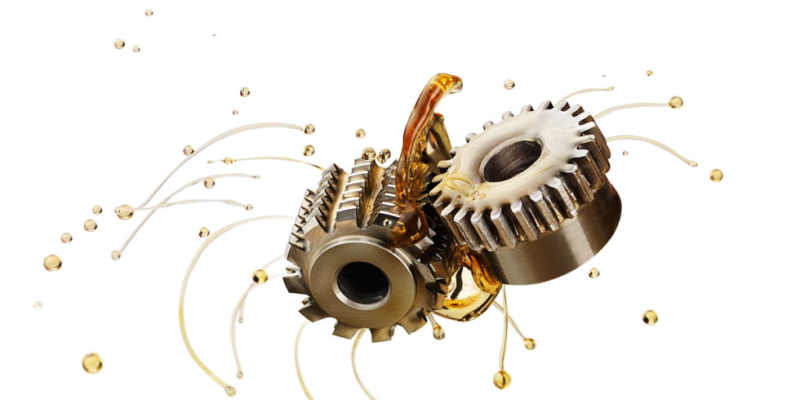

WEAR: Humankind has been faced with the problem of wear since the invention of the wheel more than 5000 years ago. Wear can be described as the removal of material from surfaces in sliding or rolling contact with each other. Wear is a universal phenomenon and rarely do two solid bodies slide over each other without a measurable material transfer or material loss, e.g. coins become worn as a result of continued contact with fabrics and human fingers. There are essentially three types of mechanical wear:

Adhesive Wear occurs during sliding when fragments of material are pulled off one surface and adhere to the other. This is the most common and least preventable type of wear.

Abrasive Wear is caused by a hard surface (or hard particles) rubbing against a soft surface. The hard material cuts and ploughs the opposing softer surface.

Surface Fatigue Wear. Repeated sliding or rolling over a surface causes subsurface cracks to initiate and grow and eventually lead to material breakup. This generally occurs if all the other wear mechanisms are very low, such as in rolling element bearings.

LUBRICATION: In a world that depends a great deal on machines, lubrication is absolutely essential. The science of tribology has advanced significantly in recent times, but the roots of lubrication extend back further than one might imagine. Lubrication in simple form has been in existence at least since the beginning of documented times.

A lubricant is a substance introduced between two surfaces, which are in relative motion to each other, to reduce friction and wear between them. Most fluids, including water, can be used as a fluid lubricant in appropriate applications. In fluid lubrication, the lubrication regime is determined by the type of lubricating film that is created and the degree of contact between two surfaces. The three distinct lubrication regimes between two sliding surfaces are Boundary Lubrication, Mixed Lubrication and Hydrodynamic Lubrication. In addition to these we also have Elastohydrodynamic Lubrication. It is the condition that occurs when a lubricant is introduced between surfaces that are in rolling contact, such as roller bearings. These lubrication regimes were discussed in detail in OilChat 22.

The early focus of tribology was to improve the efficiency and durability of machinery. Today tribology research extends to a much wider range of macro and nano disciplines in areas as diverse as the movement of continental plates, biomedical materials, computers and robotics, alternative energies, and many more.

Q8Oils offers a comprehensive range of high-quality lubricants to reduce friction and wear in a wide variety of automotive, construction, industrial, mining and agricultural applications. For more information about the complete range of Q8 lubricants, phone 011 462 1829, email us at info@bcl.co.za or visit www.bcl.q8oils.co.za.

Kinematic Viscosity:

Kinematic Viscosity: