A compressor can be described as a pump or other device that ‘inhales’ air and delivers it at a higher pressure. Compressors are also used to compress a variety of gases. The very first air compressor was the human lung. To illustrate, we use compressed air from our lungs to inflate balloons. In the early days of mankind our ancestors used their breath to stoke fires and to increase the temperature of glowing coals.

With the advent of the Metal Age more heat was required to melt metals, such as gold and copper, and circa 1 500 B.C. a basic type of air compressor, called bellows, was invented. This device was a hand-held, and later foot-operated, flexible bag made of animal skin, that produced a concentrated blast of air that was ideal for achieving higher temperature fires. In 1 762 during the early days of the Industrial Revolution John Smeaton, an innovative engineer, designed an air blowing cylinder driven by a water wheel. It soon replaced the bellows in many industrial applications.

Today compressors are generally driven by electric motors, turbines or internal combustion engines. Modern compressors come in many designs and sizes, ranging from small units at petrol stations to inflate car tyres, to massive industrial machines that are too large to fit into an average-sized garage. The air pressure in car tyres is usually between 2 and 3 bar (29.0 and 43.5 pounds per square inch). The latest high-performance compressors can deliver pressures well in excess of 70 bar (more than 1000 psi).

Lubrication plays a critical role in the efficient and reliable operation of compressors. However, before we look at compressor lubrication, we need to understand the design and operation of the most common types of compressors available on the market. Compressors are divided into two main categories: Positive Displacement and Dynamic Compressors. Following is a brief discussion of the most popular compressors within these categories:

Positive Displacement Compressors

These compressors work by filling a chamber with air. The volume of the chamber is then reduced and consequently, the pressure in the chamber is increased. By nature of their design, Positive Displacement Compressors can deliver very high pressures. The most common Positive Displacement Compressors are:

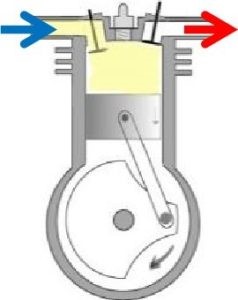

Reciprocating Piston

Reciprocating compressors function similarly to a car engine. A piston slides back and forth in a cylinder, which draws in and compresses the air, and then discharges it at a higher pressure. Reciprocating compressors are frequently multiple-stage systems, which means that one cylinder’s discharge will lead into the input side of the next cylinder. This allows for more compression than a single stage. Due to their relatively low cost, reciprocating compressors are probably the most commonly used compressors.

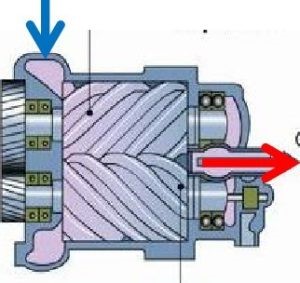

Rotary Screw

These compressors use two meshing screws (also called rotors) to compress the air. In oil flooded rotary screw compressors, lubricating oil bridges the space between the rotors. This provides a hydraulic seal and transfers mechanical energy between the driving rotor and the driven rotor. Air enters at the suction side, the meshing rotors force it through the compressor, and the compressed air exits at the end of the screws.

Rotary Sliding Vane

Rotary vane compressors consist of a rotor with a number of blades (vanes) inserted in radial slots in the rotor. The rotor is mounted offset in a housing. As the rotor turns, the blades slide in and out of the slots, keeping contact with the wall of the housing. Thus, a series of increasing and decreasing volumes are created by the rotating blades to compress the air. Centrifugal forces ensure that the vanes are always in close contact with the housing to form an effective seal.

Dynamic Compressors

Dynamic compressors use very high speed (up to 60,000 rpm) spinning blades or impellers to accelerate the air. The increased velocity causes an increase in air pressure. Dynamic Compressors deliver large volumes of air but generally at lower pressures. The following designs are the most common types of Dynamic Compressors:

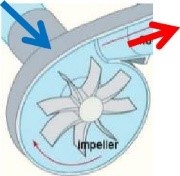

Radial Centrifugal

A rotating impeller in a shaped housing is used to force the air to the rim of the impeller, increasing the velocity of the air. A diffuser (divergent duct) section converts the velocity energy to pressure energy. Radial compressors are primarily used to compress air and gasses in stationary industrial applications.

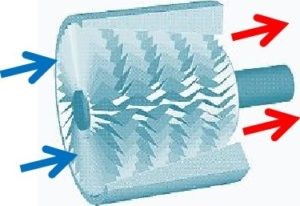

These compressors use fanlike airfoils (also known as blades or vanes) to compress air or gas. The airfoils are set in rows, usually as pairs, one rotating and one stationary. The rotating airfoils (rotors) accelerate the air. The stationary airfoils (stators) redirect the flow direction, preparing it for the rotor blades of the next stage. Axial compressors are normally used where very high flow rates are required. By nature of their design, axial flow compressors are almost always multi-stage.

The majority of compressors requires some form of lubrication to either cool, seal or minimize wear of their internal components. Many compressors are adequately lubricated by premium-grade turbine oils. We will address the specific lubrication requirements of the above compressors in more detail in our next blog, Blog 19.