An engine is assembled from many individual parts. Ensuring a good oil flow to critical areas is essential to guarantee the efficient and trouble-free operation of the engine. By lubricating an engine with the right engine oil, you can achieve smoother operation and better engine durability, saving you maintenance and fuel costs.

All engines, whether for heavy-duty vehicles or passenger cars, have critical engine parts that must be properly lubricated to avoid premature engine wear, operational problems, and catastrophic failures. In this article, we will address these critical engine components and explain how to protect them.

1. Turbocharger

A turbocharger increases the engine’s efficiency and power output by forcing extra air into the combustion chamber. Operating at high speeds of up to 250,000 rpm, a turbocharger generates excessive heat.

Risks of Turbocharger Failure

With peak temperatures of up to 1000°C, the turbocharger creates a harsh environment for engine oils. These high temperatures increase the formation of deposits in the oil, resulting in a gradual loss of power and efficiency and, eventually, severe turbocharger failures.

The Importance of Choosing the Right Lubricant

To ensure the smooth operation of the turbocharger, the engine oil must excel in cleanliness control and oxidation control to manage deposits at high temperatures. Using a high-quality lubricant helps maintain power and efficiency throughout the oil drain interval.

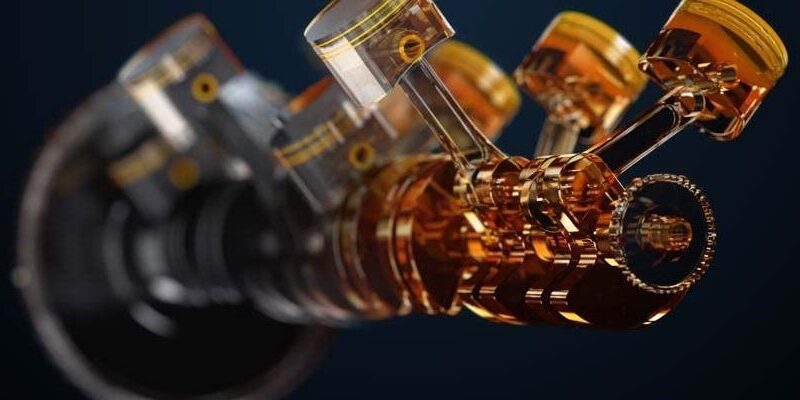

2. Piston and Liners

The engine block consists of cylinder liners, pistons, and rings. Together, they generate the combustion pressure that allows for efficient power generation. To ensure efficient combustion and maximum engine efficiency, it is crucial to prevent wear and control deposit formation in the lubricant.

Risks of Piston and Liners Failure

The formation of piston deposits can cause piston ring sticking, leading to damage to cylinder liners, pistons, and rings. This results in a loss of combustion pressure and excessive blow-by, further exacerbating oxidation and cleanliness problems.

The Importance of Choosing the Right Lubricant

A high-quality engine lubricant controls piston deposit formation and prevents wear on cylinder liners, pistons, and rings. It helps maintain optimal compression and engine power, ensuring engine durability.

3. Crankcase

The crankcase protects several key engine parts, such as the crankshaft and connecting rods, from external objects. A collection of capillary oil feeds allows for dedicated lubricant delivery to various components.

Risks of Crankcase Failure

The formation of soot and sludge can clog capillary oil feeds, resulting in crucial component failure. It also obstructs the removal of contaminants during maintenance service, leading to further wear and durability issues.

The Importance of Choosing the Right Lubricant

A lubricant that effectively controls sludge and soot ensures clean engines, guaranteeing a good oil flow to important engine components, reducing wear, and improving efficiency.

4. Valve Train

The valve train manages valve operation by controlling the amount of air and exhaust gas flowing into and out of the engine.

Risks of Valve Train Failure

The precise geometry of the cam-operated mechanism is critical for engine operation and can be affected by wear and soot formation. A lubricant with poor wear protection, inadequate soot control, and insufficient valve lubrication can result in excessive wear, reduced valve lift, and potential component failure, such as valve seat wear and related valve recession.

The Importance of Choosing the Right Lubricant

A lubricant with good wear protection and valve lubrication ensures the precise geometry of cams, valves, and valve seats, maintaining the correct air and exhaust gas ratio. As a result, the engine will maintain its power and efficiency.

5. Main and Rod Bearings

Main crankshaft bearings support the crankshaft and enable its rotation. These bearings provide oil flow to the feed holes in the crankshaft. Connecting rod bearings facilitate the rotating motion of the crank pin within the connecting rod. Both main and rod bearings are responsible for efficient lubrication with minimal power loss.

Risks of Bearing Failure

Corrosion of the bearings is a significant risk that can lead to rod and cam bearing damage and potential engine failures. Insufficient lubrication can result in oil leakage, a loss of oil pressure, and expensive component replacement.

The Importance of Choosing the Right Lubricant

A high-quality lubricant prevents corrosion and ensures extended protection of the bearings, leading to less unscheduled maintenance and significant cost savings.

Q8Oils develops all products in close cooperation with Q8 Research, an experienced team of scientists. We consider it extremely important to offer the right lubricant for any application to ensure that customers receive optimal performance and protection for their engines.