The Viscosity of a fluid is its resistance to flow. It is generally perceived as “thickness”. The higher the viscosity, the greater the resistance to flow or the “thicker” the fluid. Viscosity changes with temperature – the higher the temperature, the lower the viscosity. It is therefore always important to specify the temperature at which the viscosity measurement was made. The viscosity of lubricating oil is normally measured at 40˚C and 100˚C.

Viscosity Index (VI) is a measure of the change in viscosity with change in temperature. It is most commonly used to portray the viscosity-temperature behavior of lubricating oils. The lower the VI, the more the viscosity will change with variation in temperature. VI has no units and is calculated using the viscosity of the oil at 40˚C and 100˚C.

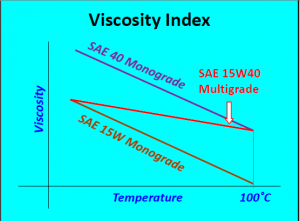

Many applications require the lubricant to perform satisfactory across a wide range of temperatures. For instance in automotive engines, an oil with a low viscosity at low temperature, i.e. SAE 15W (“W” for winter), is needed to enable the oil pump to push the oil through the engine during cold morning starts. The oil also needs to be viscous (thick) enough, SAE 40 for example, to protect the engine when it reaches operating temperature. This is when the use of a Viscosity Index Improver (VII) becomes essential.

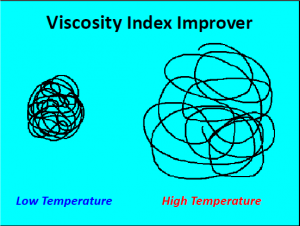

Viscosity Index Improvers (sometimes referred to as Viscosity Modifiers) are polymers that provide “thickening characteristics” to oil at elevated temperatures. When the oil temperature is low, these polymers curl up into tight balls that flow readily with the oil molecules (Figure 1). As the temperature increases, they expand into large stringy structures that restrict the normal oil flow, which has a thickening effect on the oil. When the oil cools down, the polymers go back to their original shape. The result is that when these polymer additives are blended in the correct proportion with for example SAE15W base oil, the oil flows like an SAE 15W at low temperatures and similar to an SAE 40 oil at high temperatures. The outcome is an SAE 15W40 multigrade oil that will provide adequate protection over a wide temperature range (Figure 2). It should be noted that there is actually no SAE 40 base oil in an SAE 15W40 formulation.

In addition to multigrade engine oils, Viscosity Index Improvers are also used in multigrade gear oils, automatic transmission fluids, power-steering fluids and high viscosity index hydraulic oils.

Unfortunately, viscosity index improvers have some downsides as well. The primary disadvantage is that polymers are susceptible to shearing when subjected to high mechanical stresses in severe service. There are areas in engines, gearboxes, hydraulic pumps, etcetera that have very tight clearances and this can shear the polymers (viscosity index improver molecules) into smaller pieces. This “physical breakage” cannot be reversed when the shear stresses are removed. Consequently, it affects the ability of the polymer molecules to add to the viscosity of the fluid at elevated temperatures.

Various types of polymers are used as VIIs in lubricating oil formulations. These include, amongst others, poly alkyl methacrylates (PMA), olefin copolymers (OCP) and hydrogenated styrene-diene copolymers (SDP). The various polymers have different shear stability characteristics. Higher molecular weight polymers make better thickeners but tend to have less resistance to mechanical shear. Lower molecular weight polymers are more shear-resistant, but do not improve viscosity as effectively at higher temperatures and must, therefore, be used in larger concentrations. Consequently, different VIIs must be used, for instance, in engine oils and gear applications where very high levels of sliding friction and shearing stresses are encountered.

The viscosity index improvers used in Blue Chip and Q8 lubricants products have been (i) extensively evaluated in laboratory and bench tests, (ii) specifically selected for the intended lubricant application and (iii) proven in field trials and extended service. You can, therefore, rest assured that our lubricants will resist thinning out due to shearing if used in accordance with equipment manufacturers’ recommendations.

If you have any questions concerning this newsletter or any previous ones for that matter, you are most welcome to mail us at info@bcl.co.za. Should you have any lubricant related topics you would like to see published, please do not hesitate to let us know. In fact we are always looking for new ideas. Many of the topics we wrote about in previous issues of OilChat were in response to questions and suggestions from our readers.