The topic of OilChat #47 (Soot in Engine Oil) raised further questions regarding engine oil deterioration and engine deposits, sludge and varnish in particular. Engine deposits are an ever increasing problem. This is caused by global initiatives to increase fuel efficiency and to reduce pollution of the environment.

Modern internal combustion engines operate at higher temperatures to increase thermal efficiency, oil drain intervals are extended and oil sump capacities are reduced to minimise engine size and weight. To aggravate matters airflow around the engine is reduced as a result of better aerodynamics. All of these lead to increased stresses on the oil. In addition, fuel economy pressures have led to the introduction of lower viscosity engine oils. Thin oils are more prone to ‘breaking down’ at elevated temperatures, hence the introduction of the NOACK Volatility Test. This test determines the evaporation loss of lubricants in high-temperature service. The more engine oils evaporate (vaporise), the thicker and heavier the remaining oil becomes. The collective result of all this is poor oil circulation, reduced fuel economy, as well as increased oil consumption, wear and emissions.

Oil deterioration can occur in the best maintained engines. It can also happen when the oil is still fairly new and it can even occur with synthetic lubricants. A frequently asked question is what the difference between sludge and varnish is.

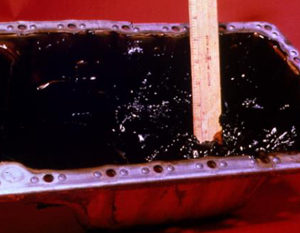

Sludge is best described as soft black deposits formed in engine oil lubricating systems. It consists primarily of oxidised lubricating oil components, water and carbonaceous residues (soot) from incomplete fuel combustion. Severely oxidized and contaminated oil can thicken to the consistency of grease.

When hot oil mixes with air, it reacts with the oxygen in the air. This process is called oxidation and it causes the oil to darken and break down to form acids and sludge. The acids are corrosive to engine metals and the sludge increases the viscosity of the oil, causing it to thicken and even gel in extreme conditions. This is significantly aggravated in diesel engines by the presence of combustion by-products. Partially burned diesel fuel (soot) gets into the oil as described in OilChat #47 and increases the viscosity dramatically. Once the oil additives are depleted the oil will break down into a gel that sticks to surfaces inside the engine. These sludge deposits restrict oil circulation and engine cooling, resulting in excessive wear, or in extreme cases, a catastrophic failure of the engine due to lack of lubrication.

Oil sludge usually starts in the top end of an engine (valve cover area) as shown in Figure 1 and in the oil sump (Figure 2). Immediate damage begins to occur when the sludge or gel blocks the oil siphon screen, as depicted in Figure 3. Once this blockage occurs, failure of the engine is inevitable. The oil level may look fine but the engine is actually being damaged with every revolution of the crank as the engine loses oil pressure and is no longer lubricated effectively. This is a serious issue for many cars built since 1996, hence the introduction of OEM oil specifications such as VW 505.00 and MB 229.3.

Figure 1 Figure 2 Figure 3

Varnish is a thin, insoluble, non-wipeable

deposit film occurring on internal engine parts. It is largely caused by oxidation of the oil. Varnish can lead to sticking and malfunctioning of close-clearance moving parts. Engine varnish is similar in appearance to lacquer.

Varnish is the result of engine oil degradation, once again largely due to elevated temperatures and the presence of oxygen in the engine. As the oil flows over hot engine surfaces, it heats up and reacts with the oxygen in the air to oxidise. Each time the oil passes over a hot surface, it oxidises a little more. This oxidation causes the early depletion of antioxidant additives in the oil, and eventually leads to the formation of insolubles, which is the beginning of varnish. The insolubles agglomerate and sooner or later stick to metal surfaces as portrayed in Figures 4, 5 and 6.

Figure 4 Figure 5 Figure 6

Varnish build-up causes excessive wear of moving parts, can lead to bearing failures and may cause critical components to seize. Other common names for varnish are lacquer, pigment, gum, and resin.

Engine oil degradation is aggravated by several other influences as discussed in OilChat #26. Poor filtration will allow contaminants, wear particles, and water to build up and infest the oil. This in turn accelerates depletion of the oil additives and allows the oil to foam. To worsen matters wear debris (mainly copper particles) act as a catalyst to promote oil oxidation.

Blue Chip Lubricants and Q8 high performance engine oils are formulated with the latest generation additive technology to control sludge and varnish effectively. Deposit formation in modern engines is an ever increasing reality, but the advanced additive chemistry in our lubricants minimises engine wear associated with oil deterioration during the life of the oil.

If you have any questions concerning lubrication, or need assistance to select suitable lubricants for your machines, simply mail us at info@bcl.co.za. Our experts are at your disposal and ready to provide you with advice and guidance.