A chainsaw is a portable, mechanical saw which cuts material with a set of teeth attached to a rotating chain that runs along a guide bar. Chainsaws are primarily used for wood cutting activities, such as tree felling, pruning and harvesting firewood. Chainsaws with specially designed bar and chain combinations have also been developed for special applications, such as cutting concrete during construction projects.

The origin of the chainsaw is debatable, but a chainsaw-like tool was made around 1830 by Bernard Heine, a German orthopedist. This instrument, the osteotome, had a chain with small cutting teeth on the chain links. The chain was moved around a guiding blade by turning the handle of a sprocket wheel. As the name implies, the tool was used to cut bone during medical procedures.

Most chainsaws are driven by petrol engines, although some models have electric motors powered by a battery or electric power cord. Petrol driven chainsaws are fitted with two-stroke engines since they do not require an oil sump like four-stroke petrol engines. The traditional lubrication method of mixing oil with the petrol of two-stroke engines allows it to work in any orientation, as there is not an oil reservoir that is dependent on gravity. This is an essential property for chainsaws because they are required to operate at any angle.

Engine emission standards have become more stringent over the last few years. To meet these standards modern chainsaw engines are designed to run on leaner oil/petrol ratios than older models. The result is that they run hotter.

Engine emission standards have become more stringent over the last few years. To meet these standards modern chainsaw engines are designed to run on leaner oil/petrol ratios than older models. The result is that they run hotter.

Lower quality two-stroke oils may not be adequate to provide satisfactory protection at these elevated temperatures. Furthermore, substandard oils do not have sufficient lubricating properties and will also leave carbon residues on pistons, cylinders and exhaust ports. This causes decreased engine performance and premature failure of vital engine components. To ensure a long, trouble-free life of a modern two cycle engine, it is essential to use the quality oil recommended by the chainsaw manufacturer. For more information about two-stroke engine lubrication please refer to OilChat numbers 44 to 46.

As a rule of thumb, most two-stroke engines these days use a 50:1 fuel/oil mix. This is a mixture of 2% oil in the petrol and is equivalent to 100ml of oil in 5L of petrol. Older chainsaws and larger

models (with engine capacity generally 70 cc and more) may well require higher oil ratios and the engine manufacturer’s recommendations should always be followed. When mixing the oil and petrol use a clean airtight container intended for fuel. Not only will it prolong the shelf life of the fuel mix, but it can also help prevent spillage, permeation and evaporation.

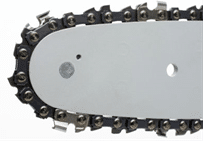

Equally important is the lubrication of the chain and bar. Without proper lubrication the working life of these critical components will be drastically reduced. The chain and bar of almost all saws are self-lubricating. They have an oil reservoir that feeds the lubricant automatically to the bar and chain when the machine is used. If a chainsaw is operating slower than normal, or the fuel tank runs dry much quicker than it should, chances are quite good that you need to add chain bar oil – and quickly. The bar and the chain run in constant contact with each other. Without lubrication, a lot of friction that could do major damage to the chainsaw, is generated.

To be effective a chain bar oil must control wear, protect against rust and corrosion and resist throw-off. To provide the desired lubricating qualities under all operating conditions, chain bar lubricants are formulated with highly refined base oils of suitable viscosity, anti-wear and/or extreme pressure additives, rust and corrosion inhibitors and tackiness agents. Anti foam additives, pour point depressants and solid lubricants may also be included in the oil formulation if required.

Finally, if the chainsaw features a sprocket at the front end of the chain guide bar, add some grease to that as well. Simply use a grease gun to give it a couple of shots of clean, high-quality general-purpose grease but remember to clean the lubrication hole first. Once the grease begins pushing out, stop and wipe the outside of the sprocket clean.

All it takes to keep your chainsaw running for years to come are a few quick maintenance steps and the correct lubricants. If you have any questions regarding chainsaw lubrication or any other lubricant related issues, simply mail us at info@bcl.co.za. Our experts are at your disposal and ready to provide you with advice and guidance.