The two primary considerations when selecting a hydraulic fluid are the viscosity grade and the hydraulic oil type. These are typically determined by the design of the hydraulic pump employed in the system and the operating temperatures and pressures. Further items for consideration are overall lubricant quality, performance requirements and base oil type. The three common varieties of hydraulic fluids found on the market today are oil-based, water-based and synthetics.

The International Standards Organization (ISO) established the ISO 6743-4 and ISO 11158 classifications of hydraulic fluids. These classification systems do not include automotive brake fluids or aircraft hydraulic fluids and generally apply to the following three primary classes of hydraulic fluids:

- Mineral Hydraulic Fluids

- Biodegradable Hydraulic Fluids

- Fire Resistant Hydraulic Fluids

Discussions in this publication will be restricted to Mineral Hydraulic Fluids and we will endeavour to provide a summary of the ISO classifications that you will find useful in understanding the most common hydraulic fluid categories. We operate in a global marketplace with equipment that is manufactured in countries from all over the world and it is very likely you may see hydraulic fluid specifications other than the ISO designations. For example, while the classifications of hydraulic fluid are set out in ISO with the designations HL, HM, HV, etc. in Germany the designations HL, HLP, HVLP are standard and frequently used in accordance with DIN 51524.

ISO and DIN are the most commonly used industry classification systems and their correlation is shown in the table below:

| DESCRIPTION | ISO | DIN |

| Mineral oil without additives | HH | H |

| Type HH/H + oxidation and corrosion-inhibiting | HL | HL |

| Type HL + wear-inhibiting | HM | HLP |

| Type HM/HLP + detergent (self-cleaning) | HLPD | |

| Type HM/HLP + viscosity-improving | HV | HVLP |

| Type HM/HLP + anti-stick-slip | HG |

Following is a short discussion of the different hydraulic oil types covered by the above classifications:

Uninhibited Hydraulic Oil

These fluids are refined mineral oils with no active ingredients (additives). They are the most basic hydraulic oils and have a relatively short service life as they are not oxidation-stable and have very limited use. Uninhibited products are in accordance with ISO HH and DIN H.

Rust and Oxidation Inhibited Hydraulic Oil

Formulated with active ingredients to increase corrosion protection and resistance to oxidation which helps the system to be protected from chemical attack and water contamination. They are used in low-pressure hydraulic systems (with no specific anti-wear requirements) in which temperatures of around 50°C are to be expected. These oils conform to ISO HL and DIN HL.

Anti-Wear Hydraulic Oil

Fluids in this category contain additives to inhibit oxidation and corrosion, as well as additives that reduce wear and/or improve the high-pressure properties of the oil. This is the most widely used type of hydraulic oil. Zinc dialkyl dithiophosphate (ZDDP) is largely employed as anti-wear additive. The presence of ZDDP, however, is not always seen as a positive, since it can attack certain metals found in some hydraulic pumps, such as silver. Furthermore, ZDDP can break down in the presence of moisture, heat and mechanical stress to form deposits. Some severe duty hydraulic pumps and other sensitive hydraulic system components (such as close clearance servo-valves and high accuracy numerically controlled machine tools) are intolerant to these deposits. Zinc-free (ashless) anti-wear hydraulic oils are recommended for sensitive hydraulic systems. Modern ashless hydraulic oils offer excellent wear protection and exhibit outstanding oxidation and thermal stability to extend oil and filter life. They also provide effective corrosion protection for copper alloys and silver pump components. Anti-wear hydraulic oils are in accordance with ISO HM and DIN HLP.

Detergent Hydraulic Oil

These fluids contain detergent additives (cleansing agents) in addition to the additives in anti-wear oils. The use of detergent hydraulic oils is approved by several hydraulic component manufacturers. They can be advantageous in many applications, such as mobile equipment, to prevent a build-up of sludge and varnish deposits, which can lead to valve sticking and other reliability problems. The main caution with these fluids is that they have water emulsifying ability, which means that water is not separated out of the fluid. Emulsified water not only reduces lubricity and filterability, but can also cause corrosion and cavitation, and reduce the life of the oil. These problems can be avoided by maintaining water content below 0.1% – which is not a low water content target for any high-performance hydraulic system. A hydraulic fluid that has the ability to emulsify small amounts of water can be beneficial in mobile equipment applications. Caterpillar, for instance, maintain that separated water drawn through the hydraulic system can damage pumps and other components. If this water freezes, it can also cause serious damage to hydraulic systems. Detergent hydraulic oils are in accordance with DIN HLPD

High Viscosity Index Hydraulic Oil

Oils which, in addition to additives that inhibit oxidation, corrosion, and wear, also contain additives that improve viscosity index (VI). These oils have a VI of higher than 140 and therefore have good viscosity/temperature characteristics. Other hydraulic oils generally have a viscosity index of around 100. The high viscosity index is achieved through the addition of VI improvers and/or by using oils with a naturally high VI. Base oil with a naturally high VI is preferable because this avoids shear-losses. If a VI improving additive is used, it is important that it has a high mechanical stability to prevent shear-losses, which would lead to a decrease in viscosity. Shear stability is a measure of the ability of the oil to withstand viscosity drop due to the breaking down of the VI improver. These oils also contain a pour point depressant to improve low-temperature performance. High VI oils are used in extreme temperature conditions (e.g. mobile hydraulics and critical systems such as CNC machine tools). High viscosity index hydraulic oils conform to ISO HV and DIN HVLP.

Anti-Stick-Slip Hydraulic Oil

Fluids falling in this category have additives to improve their stick-slip properties. Such additives prevent jerky movements, which can arise in the event of very low sliding speeds and high loads. Stick-slip resisting hydraulic oils are in accordance with ISO HG and are for example used in hydraulic elevators and cranes.

Other oil requirements you may find on a hydraulic system or in the service manual may well include one of the following specifications:

| INDUSTRY SPECIFICATIONS | EQUIPMENT MANUFACTURERS |

| AFNOR

AIST ASLE SEB |

Bosch Rexroth

Cincinnati Milacron Parker (Denison) Vickers (Eaton) |

To ensure optimum system performance, it is very important to follow hydraulic equipment manufacturers’ oil recommendations. Simply compare the manufacturer’s requirements with the specifications on the hydraulic oil label or product data sheet. If you are still in doubt our experts are at your disposal and ready to provide you with advice and answer any questions you may have. For more information please call 011 462 1829 or email lethabo@p05.4d8.myftpupload.com

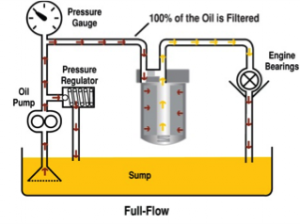

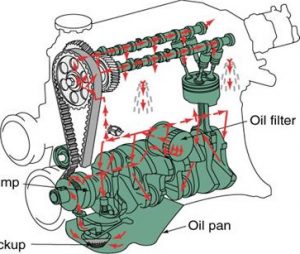

In a system where the pump is positioned higher than the oil sump, such as an automotive engine, this will present a serious problem. We will endeavour to explain this using honey as an example. At normal room temperature honey will be above its Pour Point. When you open a jar of honey and turn it upside down, the honey will flow out under the force of gravity. Yet at the same temperature, it will be impossible to suck the honey out of the jar with a straw although the honey is still above its Pour Point. Now compare this with the engine oil circulating system on the right.

In a system where the pump is positioned higher than the oil sump, such as an automotive engine, this will present a serious problem. We will endeavour to explain this using honey as an example. At normal room temperature honey will be above its Pour Point. When you open a jar of honey and turn it upside down, the honey will flow out under the force of gravity. Yet at the same temperature, it will be impossible to suck the honey out of the jar with a straw although the honey is still above its Pour Point. Now compare this with the engine oil circulating system on the right.

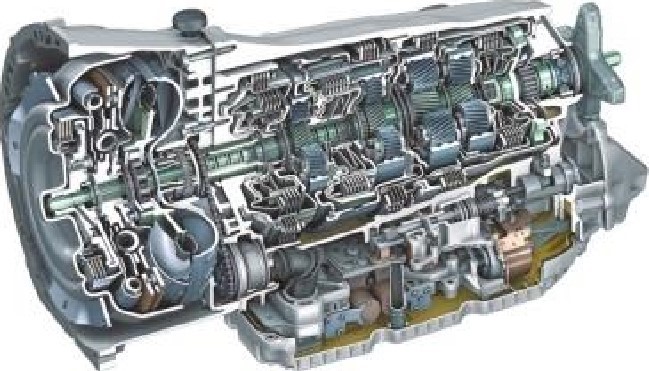

and drivability. Various top of the range luxury cars are now available with eight-, nine- and even ten-speed auto boxes. These transmissions are incredibly sophisticated with many of them requiring their own specific fluid formulations, such as the Mercedes-Benz 9G-Tronic transmission on the right.

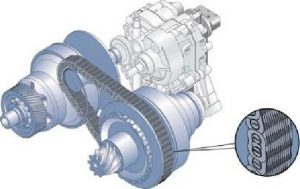

and drivability. Various top of the range luxury cars are now available with eight-, nine- and even ten-speed auto boxes. These transmissions are incredibly sophisticated with many of them requiring their own specific fluid formulations, such as the Mercedes-Benz 9G-Tronic transmission on the right. In CVT’s fitted to cars the rubber belt is replaced with a metal belt or chain running between the variable-diameter pulleys. This poses a unique set of different challenges as opposed to traditional ATF’s such as requiring higher shear stability and maintaining the appropriate amount of metal-to-metal friction while having enhanced anti-shudder performance. As in the case of ATF’s, there is not one universal CVT fluid that is suitable for all Continuously Variable Transmissions.

In CVT’s fitted to cars the rubber belt is replaced with a metal belt or chain running between the variable-diameter pulleys. This poses a unique set of different challenges as opposed to traditional ATF’s such as requiring higher shear stability and maintaining the appropriate amount of metal-to-metal friction while having enhanced anti-shudder performance. As in the case of ATF’s, there is not one universal CVT fluid that is suitable for all Continuously Variable Transmissions.

In some engines oil returning to the sump, drips on the rotating crankshaft and is thrown around to lubricate the pistons, rings and cylinder walls. In other designs, small holes are drilled through the piston connecting rods to spray oil on the pistons and cylinder walls.

In some engines oil returning to the sump, drips on the rotating crankshaft and is thrown around to lubricate the pistons, rings and cylinder walls. In other designs, small holes are drilled through the piston connecting rods to spray oil on the pistons and cylinder walls.

To improve (reduce) the pour point of these oils, pour point depressants (PPDs) are added. PPDs do not in any way affect the temperature at which wax crystallizes or the amount of wax that precipitates. They simply ‘coat’ the wax crystals preventing them to interlock and forming three-dimensional structures that inhibit oil flow. Good PPDs can lower the pour point by as much as 40 0 C, depending on the molecular weight of the oil.

To improve (reduce) the pour point of these oils, pour point depressants (PPDs) are added. PPDs do not in any way affect the temperature at which wax crystallizes or the amount of wax that precipitates. They simply ‘coat’ the wax crystals preventing them to interlock and forming three-dimensional structures that inhibit oil flow. Good PPDs can lower the pour point by as much as 40 0 C, depending on the molecular weight of the oil.

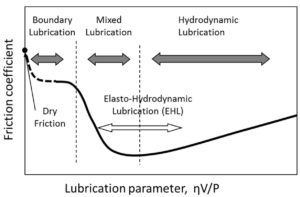

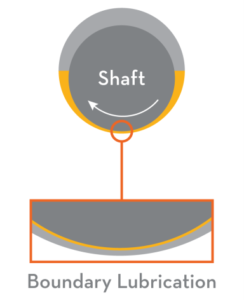

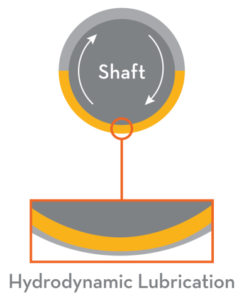

imes, we need to look at how friction and wear occur between moving machine surfaces. These surfaces appear smooth to the naked eye, but they are actually rough and uneven. Tiny peaks called asperities stick out and scrape against asperities on the opposing surface, causing friction and wear. The prime function of a lubricant is to prevent, or at least reduce, wear between surfaces moving on one another. We will endeavour to explain the lubrication of a plain journal bearing in parallel to the skiing analogy above. To enable the shaft to rotate in the bearing on the left, the diameter of the shaft must be less than the inside diameter of the bearing. This creates a wedge similar to the one between the skis and the water.

imes, we need to look at how friction and wear occur between moving machine surfaces. These surfaces appear smooth to the naked eye, but they are actually rough and uneven. Tiny peaks called asperities stick out and scrape against asperities on the opposing surface, causing friction and wear. The prime function of a lubricant is to prevent, or at least reduce, wear between surfaces moving on one another. We will endeavour to explain the lubrication of a plain journal bearing in parallel to the skiing analogy above. To enable the shaft to rotate in the bearing on the left, the diameter of the shaft must be less than the inside diameter of the bearing. This creates a wedge similar to the one between the skis and the water. he shaft and bearing asperities in a lubricated system will be in physical contact. The major portion of wear in any machine takes place in this regime. To prevent excessive wear within this regime, lubricants are formulated with additives to form a low-friction, protective layer on the wear surfaces. The base oil of the lubricant acts as a carrier to deposit the additives where they are needed. A suitable viscosity is important to ensure the oil can flow into tight spaces to lubricate the surfaces. The additive chemistry (anti-wear or extreme pressure) used within the lubricant is determined by the application.

he shaft and bearing asperities in a lubricated system will be in physical contact. The major portion of wear in any machine takes place in this regime. To prevent excessive wear within this regime, lubricants are formulated with additives to form a low-friction, protective layer on the wear surfaces. The base oil of the lubricant acts as a carrier to deposit the additives where they are needed. A suitable viscosity is important to ensure the oil can flow into tight spaces to lubricate the surfaces. The additive chemistry (anti-wear or extreme pressure) used within the lubricant is determined by the application.

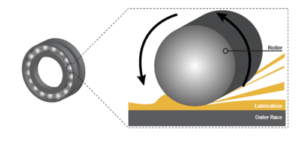

the pressure that develops is sufficient to separate the roller and raceway completely. In fact, the pressure is high enough for the surfaces to deform elastically. The deformation only occurs in the contact zone, and the metal elastically returns to its normal form as the rotation continues, hence the term elastohydrodynamic lubrication. This lubrication regime may be compared to a car tyre aquaplaning on water. It occurs when water on the road accumulates in front of the tyre faster than the weight of the car can push push it out of the way.

the pressure that develops is sufficient to separate the roller and raceway completely. In fact, the pressure is high enough for the surfaces to deform elastically. The deformation only occurs in the contact zone, and the metal elastically returns to its normal form as the rotation continues, hence the term elastohydrodynamic lubrication. This lubrication regime may be compared to a car tyre aquaplaning on water. It occurs when water on the road accumulates in front of the tyre faster than the weight of the car can push push it out of the way.