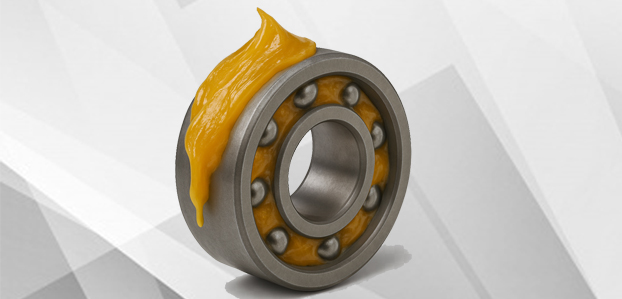

Grease problems can be frustrating because so much happens out of sight, deep inside the machine, but by paying attention to small warning signs – like temperature changes, grease consistency, colour or leakage – you can detect problems at an early stage. In this final edition of our three-part series dealing with common grease problems we are focusing on some further issues you may be faced with.

Premature Bearing Wear. Bearings wearing out too early can result from mechanical issues, like overloading, misalignment, incorrect sizing or poor lubrication practices — including the use of grease with a too low base oil viscosity or lack of extreme pressure (EP) additives.

Solution: Conduct a full failure investigation. Examine loading, alignment, grease selection and relubrication practices before jumping to conclusions. It is often a combination of factors and not a single cause.

Grease Washing Out with Water. Water washout is a common headache for shielded bearings (bearings with metal shields that provide only moderate protection against contaminants) or equipment exposed to washdown, rain or process water.

Solution: Upgrade to a grease designed for wet conditions. Always look for “hydrolytically stable” grease formulations.

Grease Turns Dark or Black. Grease that darkens often signals oxidation, bearing debris contamination or overheating. In extreme cases stray voltage or electrostatic discharge inside the bearing can cause arcing damage, which is visible as pitting or fluting (formation of grooves).

Solution: Do a sniff test for burnt smells, check machinery grounding and inspect bearings for electrical arcing marks. If needed, send a sample to a lab for contaminant analysis.

Grease Turns Milky. If grease turns milky, water contamination is usually the culprit. Some thickeners naturally absorb water, while others resist it more efficiently. Mild contamination does not always ruin grease, but it will usually shorten its service life.

Solution: Eliminate the water source. Choose a grease that either sheds water well or emulsifies water effectively, like a calcium sulfonate grease.

Bearings Overheating. One of the most common causes of bearings overheating is simply over-greasing. Excess grease increases internal pressure, destroys bearing seals and leads to higher operating temperatures. Lubricant starvation, though less common, can also cause overheating.

| Page 1 of 2 |

Solution: Add small amounts of grease at a time and monitor temperature changes. If temperatures drop, increase the greasing frequency slightly. If they rise, purge excess grease and reduce the fill amount. High-speed bearings may need a grease with a lower base oil viscosity.

Always work with your lubricant supplier and/or OEM to select the right grease for your application. Before switching products, verify compatibility with a controlled trial and monitor performance closely. Sometimes a heavier grease or higher-viscosity oil can mask underlying mechanical problems, but unless you fix the root cause, failures will return.

If you have any questions concerning grease in general or want to find out more about our comprehensive range of lubricants, phone 011 462 1829 or email us at info@bcl.co.za.

We would also like to make use of this opportunity to wish all our readers, customers and followers a wonderful Festive Season and a prosperous New Year. We are certainly looking forward to being of service to you again in 2026.

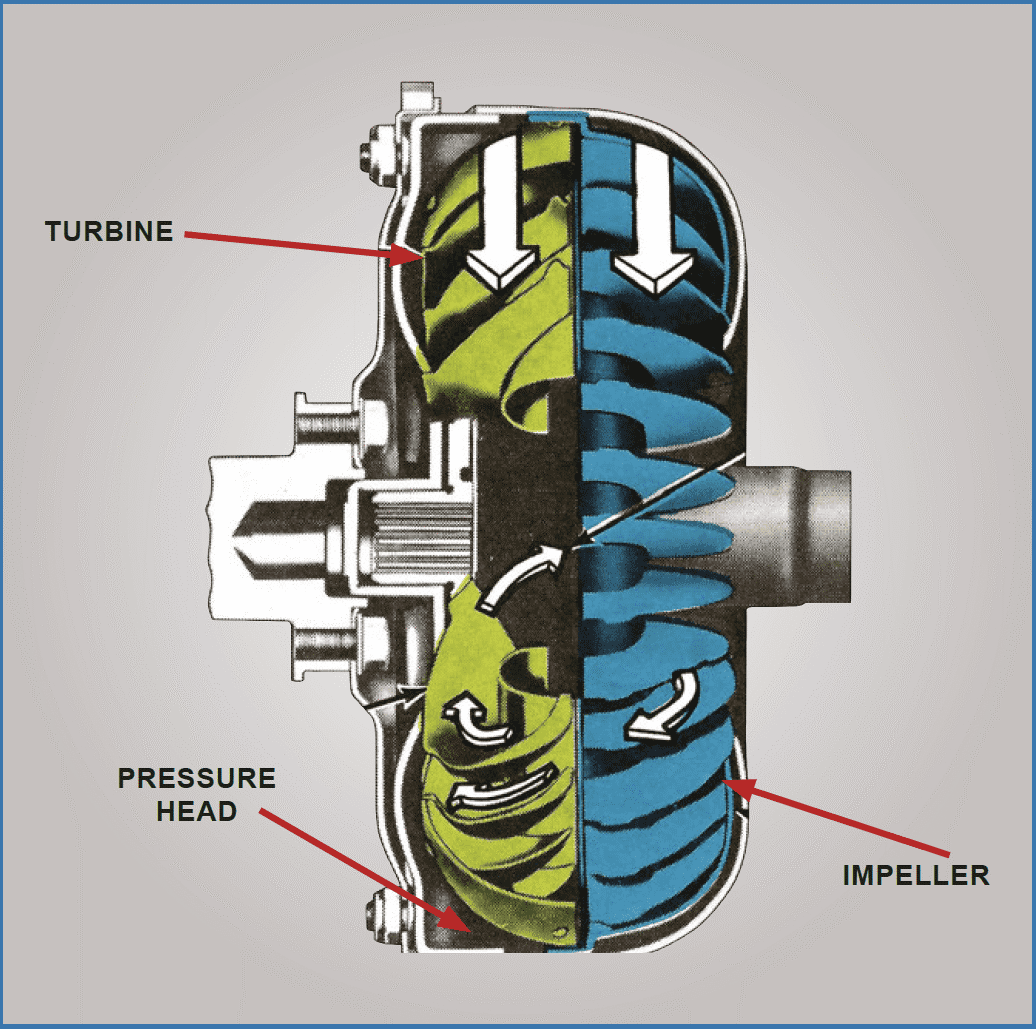

The torque converter housing is a doughnut shaped sealed unit. Inside the housing are two large ‘fans’ (the impeller and the turbine), a smaller ‘fan’ (the stator) and oil (torque fluid). The housing and impeller are attached to the flywheel and always spin at the same speed as the engine. The turbine is connected to the automatic transmission. As the impeller rotates, it forces the oil to the outside (by means of centrifugal force) and onto the fins of the turbine which causes it to spin and rotate the transmission.

The torque converter housing is a doughnut shaped sealed unit. Inside the housing are two large ‘fans’ (the impeller and the turbine), a smaller ‘fan’ (the stator) and oil (torque fluid). The housing and impeller are attached to the flywheel and always spin at the same speed as the engine. The turbine is connected to the automatic transmission. As the impeller rotates, it forces the oil to the outside (by means of centrifugal force) and onto the fins of the turbine which causes it to spin and rotate the transmission. The stator is located in the centre of the torque converter between the impeller and the turbine. Its main function is to redirect the oil returning from the turbine back to the impeller as shown on the right. This increases the efficiency of the torque converter considerably.

The stator is located in the centre of the torque converter between the impeller and the turbine. Its main function is to redirect the oil returning from the turbine back to the impeller as shown on the right. This increases the efficiency of the torque converter considerably.

Today we drill down through the layers of sand and sedimentary rock to reach the porous rock formations that contain the oil and gas deposits. Contrary to what you may have believed up to now, extracting the crude oil is more like sucking liquid from a sponge with a straw than from a puddle of liquid.

Today we drill down through the layers of sand and sedimentary rock to reach the porous rock formations that contain the oil and gas deposits. Contrary to what you may have believed up to now, extracting the crude oil is more like sucking liquid from a sponge with a straw than from a puddle of liquid.

Wire ropes are made up of multiple strands of wires twisted together. Each strand consists of several wires, and the strands are then twisted around a core (which can also be made of wires or other materials) as shown on the right. The construction allows for flexibility and strength, making wire ropes suitable for heavy lifting and rigging applications such as cranes, elevators, mine hoists and marine applications.

Wire ropes are made up of multiple strands of wires twisted together. Each strand consists of several wires, and the strands are then twisted around a core (which can also be made of wires or other materials) as shown on the right. The construction allows for flexibility and strength, making wire ropes suitable for heavy lifting and rigging applications such as cranes, elevators, mine hoists and marine applications. The extent to which wires move in a rope when it bends, is illustrated by the example of what actually happens when you wrap a 1 inch (25 mm) rope over a 30 inch (760 mm) sheave. The circumference of a 32 inch circle is slightly more than 6 1/4 inch longer than that of a 30 inch circle. Since the rope only touches half of the sheave at any time, the length differential which the rope must accommodate is 3 1/8 inch – almost 80 mm. This change of dimension is achieved by the sliding and adjusting of the strands in relation to one another, and a similar sliding and adjusting of the individual wires within each strand.

The extent to which wires move in a rope when it bends, is illustrated by the example of what actually happens when you wrap a 1 inch (25 mm) rope over a 30 inch (760 mm) sheave. The circumference of a 32 inch circle is slightly more than 6 1/4 inch longer than that of a 30 inch circle. Since the rope only touches half of the sheave at any time, the length differential which the rope must accommodate is 3 1/8 inch – almost 80 mm. This change of dimension is achieved by the sliding and adjusting of the strands in relation to one another, and a similar sliding and adjusting of the individual wires within each strand.