In this edition of the newsletter, we will endeavour to explain what slideway lubricants are, their functions and how they work.

Slideway oils derive their name from the application. They are primarily designed for the lubrication of machine tool slideways. A slideway can be described as any form of track along which things can slip or slide. A curtain rail is a simple example of a slideway.

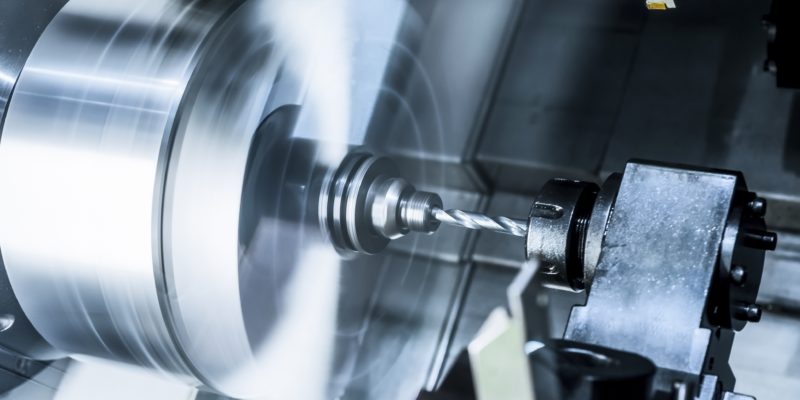

In metalworking operations, workpieces are machined into a desired shape and size by a controlled metal removal process. In  general cutting operations (e.g. lathes) the workpiece rotates whilst the cutting tool is stationary. Metal may also be removed by means of linear instead of rotational movement. In these operations, the workpiece and cutting tool move in a straight line relative to each other. The photo on the right shows such a machining operation. The cutting head (in the red rectangle) is attached to the light grey frame and can move up, down or to the left and right on slideways. The brown workpiece is fixed to a traverse table that moves backward and forward, also on slideways. The operator (with green pants) is visible on the left side of the photo. These metalworking machines can vary in size from modest basic units that produce small metal components to massive monsters designed to machine very large workpieces such as marine engines and mining machinery.

general cutting operations (e.g. lathes) the workpiece rotates whilst the cutting tool is stationary. Metal may also be removed by means of linear instead of rotational movement. In these operations, the workpiece and cutting tool move in a straight line relative to each other. The photo on the right shows such a machining operation. The cutting head (in the red rectangle) is attached to the light grey frame and can move up, down or to the left and right on slideways. The brown workpiece is fixed to a traverse table that moves backward and forward, also on slideways. The operator (with green pants) is visible on the left side of the photo. These metalworking machines can vary in size from modest basic units that produce small metal components to massive monsters designed to machine very large workpieces such as marine engines and mining machinery.

Smooth and precise slideway operation is essential to ensure optimum machine tool productivity since loss of frictional control can cause inaccuracies of the machined workpiece surfaces. To fully understand slideway lubrication we need to revisit the fundamentals of friction and lubrication – please refer to OilChat 22. The speed/friction relation between two lubricated surfaces is illustrated by the curve on the second page of OilChat 22. The three different lubrication regimes are:

- Boundary Lubrication is associated with metal-to-metal contact when the speed difference between two moving surfaces is too low to prevent contact between the two lubricated surfaces.

- Mixed Lubrication is a transitional regime between the boundary and hydrodynamic lubrication when the speed is not sufficient to separate the two surfaces completely.

- Hydrodynamic Lubrication occurs when the speed is high enough to separate the two moving surfaces completely and friction is at its lowest.

In machining operations, the traverse table stops at the end of the slideway and starts to move in the opposite direction. When the table stops, static friction (the worst form of boundary lubrication) occurs. As the table speed increases, friction changes from static to dynamic. This fluctuation between static and dynamic friction results in a jerky movement which is commonly referred to as stick-slip. In simple terms stick-slip can be described as surfaces alternating between sticking to each other and sliding over one another. Static (stationary) friction between two surfaces is greater than dynamic (moving) friction. If the applied force is large enough to overcome the static friction, the reduction in friction to the dynamic state can cause a sudden increase in the velocity of the movement resulting in the jolting action. Stick-slip can also occur at low feed speeds and high loads. Since stick-slip is a recurring event, it may be perceived as a harmonic vibration or noise.

While it may not always be visible to the human eye, stick-slip effects are a frequent phenomenon in everyday life and it produces a range of audible incidents, e.g. when a chair is pushed along the floor its legs begin to vibrate with an irritating noise. Other examples of stick-slip motion are the sound produced by a wine glass when a wet finger is moved along its rim and the jerky motion of vehicle windshield wipers. Stick-slip, however, is not always a bad phenomenon. It is responsible for the rich sounds when a bow is moved over the strings of a violin. In machining operations, stick-slip is an undesirable occurrence that causes the transverse table and workpiece to shudder resulting in inaccuracies of the machined surfaces.

Slideway lubricants are therefore formulated with special friction modifying additives to control stick-slip and chatter under all operating conditions including:

- Static friction situations during start-up.

- Continuous transition from rest to movement.

- Slow speed heavy load applications.

In addition, high-performance slideway lubricants must contain additives to provide good antiwear and extreme pressure performance, tackiness for slideway adhesion, oxidation stability, as well as rust and corrosion protection for slides and ways. Slideway oils must also have good compatibility with cutting oils and other machine tool lubricants and adequate demulsibility to separate from cutting fluid emulsions.

The most common slideway lubricant viscosity grades are ISO 68 and ISO 220 with the following application guidelines:

ISO 68: Horizontal slideways and light to moderate applications.

ISO 220: Vertical slideways and more severe applications.

Slideway oils in the appropriate viscosity grade are also recommended for hydraulic systems subject to stick-slip service (ISO 11158 Type HG), heavily loaded gear systems and other industrial applications requiring an adhesive, corrosion inhibited lubricant with EP properties.

If you have any questions concerning slideway lubrication our experts are at your disposal and ready to provide you with advice and guidance. Simply mail us at info@bcl.co.za.